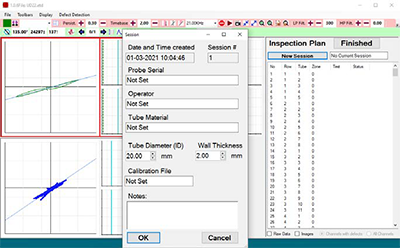

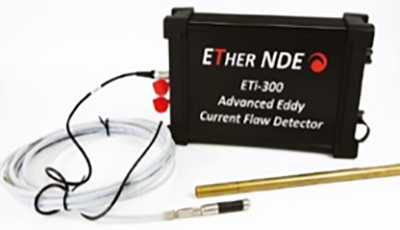

| Operating Modes |

Eddy Current Modes |

Eddy Current Single Probe Frequency |

| Eddy Current Dual Probe Frequency |

Eddy Current 1 Probe up to 4 Channels (e.g. 3 Frequencies Bridge Differential and 1 Frequency

Absolute or 2 Frequencies Bridge Differential and 2 Frequencies Absolute). |

| Eddy Current 2 Probe up to 2 Channels each (e.g. Dual Probe each with Dual Frequency Bridge Differential). |

| Probes |

Connectors |

12-Way LEMO 2B (Absolute, Bridge, Reflection, Rotary) |

| 12-Way LEMO 2B (Bridge, Reflection) |

| BNC - Absolute |

| Simultaneous probe operation using x2 LEMO 12 way |

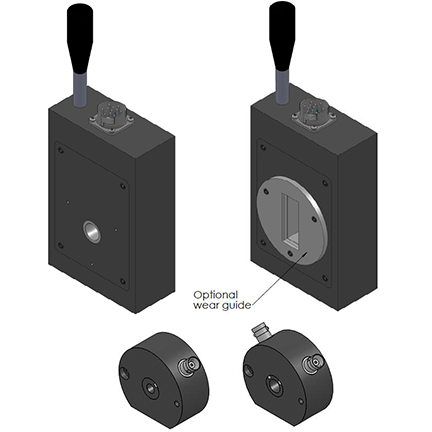

| Rotary |

600-3000 rpm. ETher Mercury Drive (ADR002), Hocking 33A100, Rohmann MR3, SR1 and SR2

Drive (special adapter needed) |

| Frequency |

Multi-Frequency |

10Hz - 12.8MHz (no limit on frequency, all channels) |

| Gain |

Overall |

-18 to + 104dB, 0.1, 1 and 6dB steps |

| Input |

0dB or 12dB |

| Drive |

0dB, 6dB and 10dB (0dB reference 1mW into 50 ohm). |

| Max X/Y Ratio |

+/-100.0 dB |

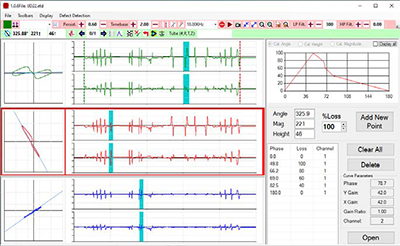

| Phase |

Range |

0.0-359.9°, 0.1° steps |

| Filters |

Sample Rate |

Constant 16kHz overall over 4 times X/Y pairs |

| High Pass |

DC to 2kHz or Low Pass Filter, which ever is lower in 1Hz steps. Plus variable adaptive balance

drift compensation 0.01 - 0.5 Hz (6 steps). |

| Low Pass |

1Hz to 4kHz or a quarter of the lowest test frequency, which ever is lower in 1 Hz steps. |

| Balance Load |

Manual |

14 internal balance loads; 2.2μH, 6.0μH, 7.0μH, 8.2μH, 12μH, 15μH, 18μH, 22μH, 30μH, 47μH,

82μH, 330μH, 820μH and 3,300μH |

| Automatic |

Optimized balance load selection. |

| Mix Channel |

Frequency |

Full frequency range available on all channels |

| Number of Mixers |

8 maximum user definable configurations |

| Operations |

Automatic or Manual |

| Mix Gain |

X/Y -18 to +18dB |

| Mix Phase |

0.0-359.9°, 0.1° steps |

| Connectivity |

USB |

Full speed USB 2.0 12.5 MB/s |

| l/O |

8 way LEMO 4 configurable TTL Level with 5v eg encoder input |

| Power |

External |

100-240 v 50-60Hz 30 Watts |

| Battery |

Internal 7.2V nominal @ 3100mAh = 22.32 watt.hr |

| Running Time |

Up to 15 hours with a 2MHz Pencil Probe 30%, up to 8 hours with a Rotary Drive 50% duty cycle. |

| Charging Time |

2.5 hrs. charge time, Simultaneous charge and operation |

| Power On Self-test |

The systems performs a self-test on start up. |

| Physical |

Weight including Internal Battery |

6.17 lbs. (2.8 kg) |

| Dimensions |

8.5" x 3.6" x 13.5" (214 x 90 x 342 mm) (w x h x d) |

| Material |

High impact-resistant Aluminum enclosure with tough silicon elastomer edge protection. |

| Operating Temp. |

-5° to 140°F (-20° to 60°C) |

| Storage Temp. |

Storage for up to 12 months -5° to 95°F (-20° to 35°C). Nominal 68°F (20°C) |

| IP Rating |

IP66 |

| Verification Level |

|

The system includes on delviery a 2 year validity Verification Level 2, detailed function check and calibration as per ISO 15548-1:2013. |