The Eddycon D is a universal multi-channel eddy current flaw detector designed to solve a wide range of tasks. It uses the Ethernet port to connect to stationary PCs, portable laptops or tablets using specially configured software to create high performance systems for non-destructive testing. The Eddycon D is integrated with many automated systems including the powerful, automated SmartScan FA Aircraft Wheel Inspection system.

Mechanized and Automated Testing of Rails/Profiled Bars

The Eddycon D can perform high efficient, 100% eddy current testing of rolling surface, rail foot, head and side surfaces, shown here equipped to a mechanized scanner. Allows for arranging a high speed industrial communication between individual test positions, scanning units and server stations via Wi-Fi. This makes mechanized and automated eddy current testing of rails and profiled bars easy. Building an automated eddy current system for rails testing equipped with an Eddycon D multichannel flaw detector into a production line avoids the necessity of 'balancing' on each rail to be tested due to the ability to save the balancing parameters on the calibration block.

Automated Testing of Pipes and Round Bars

The photo above shows a SNK T-18 VT automated system equipped with an Eddycon D. This system is able to test up to 30 pipes per hour with outer diameters of 245 mm. Using an Eddycon D allows for implementation of high-performance multichannel systems, ensures easy integration into the existing production line, and guarantees 100% eddy current testing with automatic recording and saving of test results. High frequency measurements provided by the Eddycon D allows for designing high speed rotary systems for pipes and bars testing, using the rotary ECPs for detection of unacceptable surface flaws.

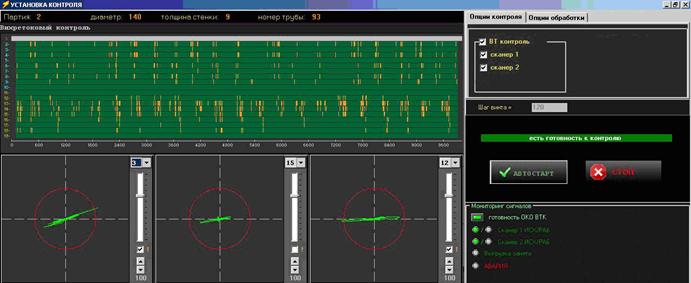

Testing Screen

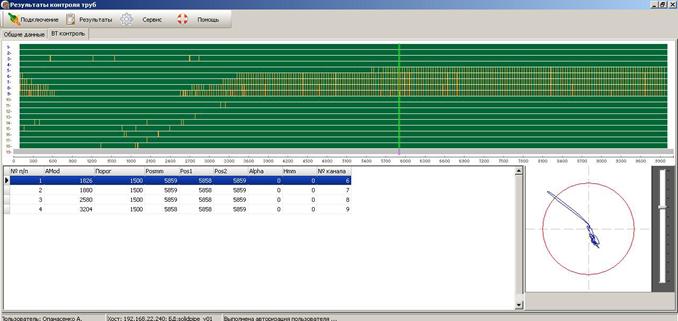

Test Results Screen

Setting Up EC Channel

This program ensures rapid set up of all EC Channel parameters including frequency, generator out-put voltage, gain, filers, threshold level type, encoder and more. It also allows for creation of settings with unique names, 4 independent threshold levels for automated defect triggering and estimating the defect depth and length

Testing

The Testing software includes a real-time display of EC probe information, displays the status of mechanisms and units on a mnemonic scheme, testing process control and records the testing results into the PC or tablet memory.

Reviewing Test Results

Test results can be sorted and retrieved by various characteristics, as well as be reviewed from the remote PC, tablet, etc. This software can also generate testing protocols and archive the test results.

| General Specifications | |

| Overall Dimensions | 293 x 37 x 141 mm |

| Weight | 1 kg |

| Number of EC Probes Connected to One EC Channel | >128 |

| ECP Connectors | Lemo 12, Lemo 00 |

| Power | 12 V DC Power |

| Time for Operating Mode Setup | Up to 1 minute |

| Warranty | 1 Year |

| Generator | |

| Output Voltage (Double Amplitude) | 0.5 - 20 V, Peak-Peak |

| Frequency Range | 10 Hz to 16 MHz |

| Synchronization Type | Internal, from encoder, from rotary ECP |

| Inputs / Outputs | |

| Ethernet | Yes |

| Synchronous Input | Yes |

| Encoder Output | 1 axis Encoder line |

| Receiver | |

| Gain | 0 to 70 dB with a step 1, 10 dB |

| Input Signal | 0.5 V from Peak to Peak |

| Digital Filters | High frequency, Low frequency, Bandpass |

| Main Metrological Specifications | |

| Protection Level | IP 64 |

| Environment Humidity | -10 to 45 C |

| Atmospheric Pressure | 84 to 106.7 kPa |

| Full Average Lifespan | >10 years |