| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| ML-3000 Daylight Fluorescent Scanner | UV-ITEC-ML3000 |

|

Request Pricing | ||

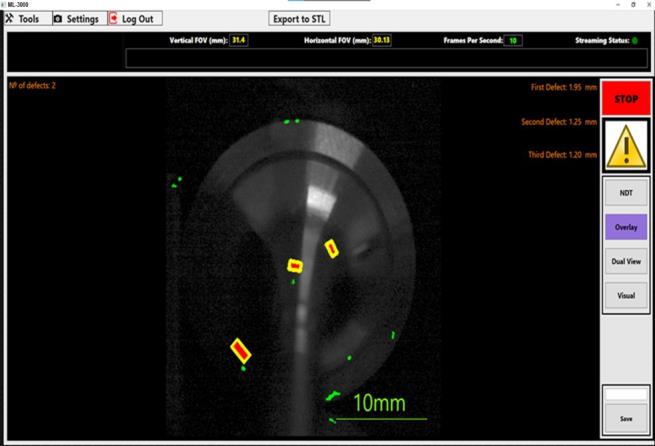

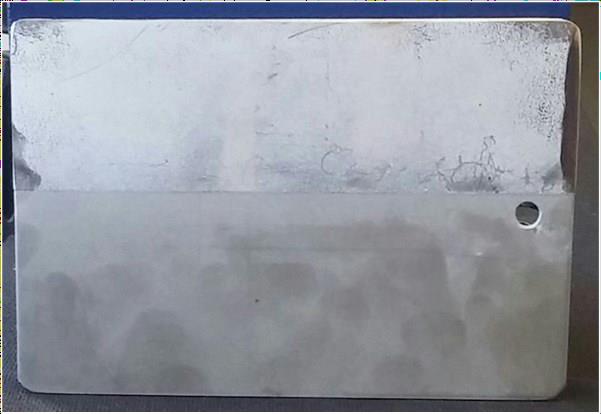

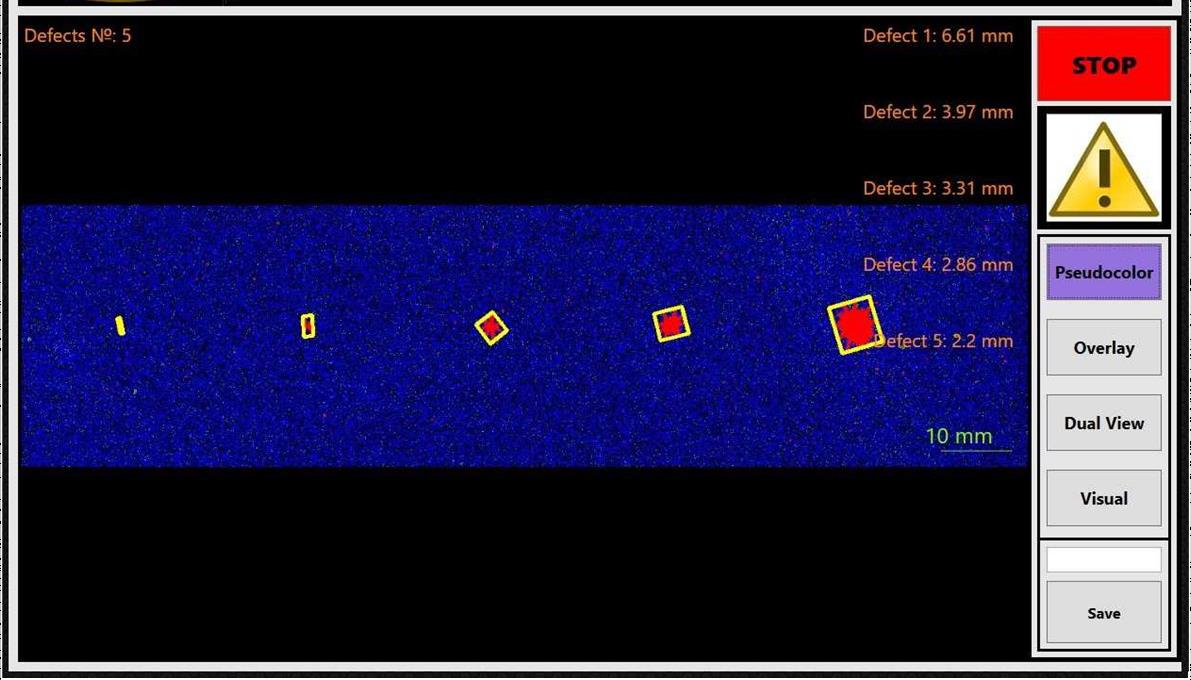

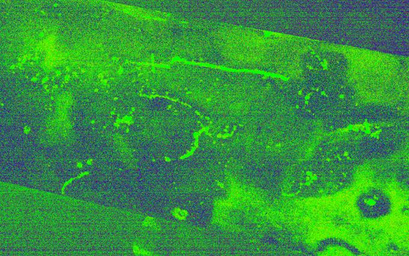

The ML-3000 Daylight Fluorescent Scanner provides fast and accurate detection of fluorescence signals in environments with strong background light. This revolutionary inspection system for the aerospace, automotive, and associated industrial sectors provides quality assurance and cuts inspection time.

The ML-3000 detects and extracts fluorescence signals with intensity levels less than 20-lux, from background daylight of up to 100,000-lux.

The ML-3000™ is designed for automated NDT inspection in high-volume manufacturing. Equally applicable to components too big or heavy to move into a darkened inspection room. Industries include:

| Industries and Applications | Inspection Types | Detectable Defects |

|

|

|

Find, size, and count clusters; measure the spacing between them

|

|

|

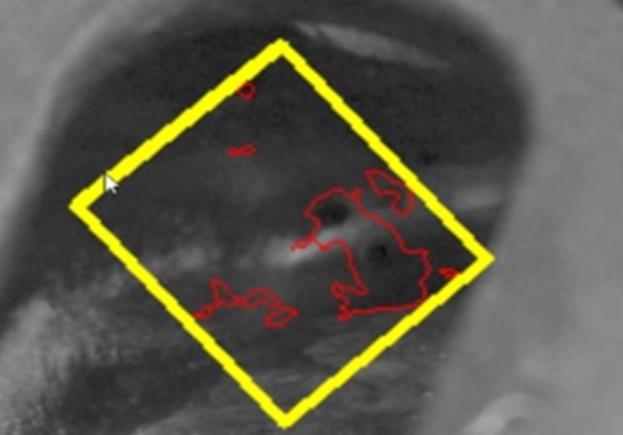

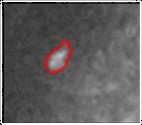

Extracts levels of fluorescence in daylight too low to be seen by the human eye and automatically sizes them to TAM panel tolerances

|

|

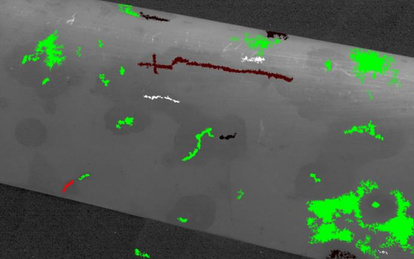

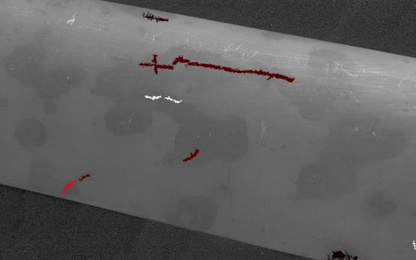

The ML-300 utilizes automated inspection and detection software that replaces human inspectors with consistent, objective analysis.

User Defined Acceptance Criteria: Software filters based on intensity, size, and shape. Uses various digital filters to isolate user-defined indications based on their geometric characteristics.

| Image Processing | Display Modes | Data Management |

|

|

|

|

|

|

User Defined Acceptance Criteria: Software filters based on intensity, size and shape. Uses various digital filters to isolate |

DISPLAY CRACKS |

| Technical Specifications ML 3000 | |

| Dimension: | 78.7 x 66.9 x 39.4 inches (200 x 170 x 100 mm) |

| Weight: | 2.6 lb (1.2 kg) |

| Mounting: | 4 point mounting plate |

| Current: | 3 A |

| Service Life (LEDs): | 30,000 hrs |

| Intensity: | Typical irradiance of 4500 µW/cm² at 15.0 in (38 cm) |

| UV-A Wavelength: | Peak at 365 nm ± 5 nm |

| UV-B Wavelength: | 100% Free |

| UV-C Wavelength: | 100% Free |

| Maximum Beam Diameter: | 5.9 in (15 cm) |

| FWHM: | < 15 nm |

| Visible Light: | < 10 lux at 15.0 in (38 cm) |

| Working Temperature: | 32°F to 113°F (0°C to 45°C) |

| Barrel Material: | Anodised aluminium |

| Rating: | IP65 |

| Warranty: | 2 Years |

| Certifications: |

|

| Calibrated Standard | 15 Averages | RMS Difference |

| 0.125 inches (3.2 mm) | 0.126 inches (3.2 mm) | 0.001 inches (0.0 mm) |

| 0.090 inches (2.3 mm) | 0.092 inches (2.3 mm) | 0.002 inches (0.1 mm) |

| 0.060 inches (1.5 mm) | 0.061 inches (1.5 mm) | 0.001 inches (0.0 mm) |

| 0.045 inches (1.1 mm) | 0.046 inches (1.2 mm) | 0.001 inches (0.0 mm) |

| 0.030 inches (0.8 mm) | 0.029 inches (0.7 mm) | -0.001 inches (0.0 mm) |

| 0.025 inches (0.6 mm) | 0.026 inches (0.7 mm) | 0.001 inches (0.0 mm) |

| Specification | Value |

|---|---|

| Packaged Weight: | 5.1 lb (2.3 kg) |

| Packaged Dimensions: |

H: 11.2 in x W: 13.0 in x D: 5.9 in (H: 285 mm x W: 330 mm x D: 150 mm) |

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| ML-3000 Daylight Fluorescent Scanner | UV-ITEC-ML3000 |

|

Request Pricing | ||