| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| Sonatest WP2 Wheel Probe 2 - 64 Element | UT-ST-WP2-64 |

|

Request Pricing | ||

| Sonatest WP2 Wheel Probe 2 - 128 Element | UT-ST-WP2-128 |

|

Request Pricing | ||

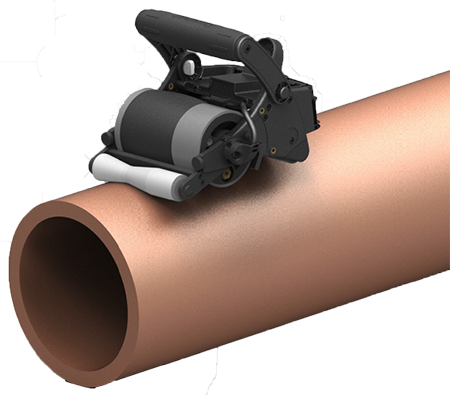

The WheelProbe 2 is Sonatest's newest generation of Wheel Probe, achieving unrivalled, excellent results in the field of composite inspection and corrosion monitoring with speed and ease of use. This innovative probe features a wireless control unit, 3 function buttons and status LEDs, a rugged and light reinforced frame, ergonomic handles, detachable cable, and a security hook. With precision engineered rollers the WP2 has the best acoustic on the market and can be used on flat and curved surfaces.

Typical applications included: Corrosion Mapping, Marine Inspection, Aerospace Fuselage, Aerospace Large Area scanning and Automotive Testing.

The WheelProbe 2 is available in two formats: the WP2 64 & WP2 128. 64 & 128 denote the number of elements in each wheel.

The WP2 64 format is the standard model and has center frequency options of 2 MHz, 3.5MHz, 5MHz and 10MHz, and a total active length of 2".

The WP2 128 format has center frequency options of 1 MHz, 2MHz, 3.5MHz, 5MHz and 10MHz. It has a total active length of 4".

For a full comparison of both options, see technical specifications.

New roller design with re-engineered water management including clear side plates for bubble tracking, pressurized pump with needle and new purge valve.

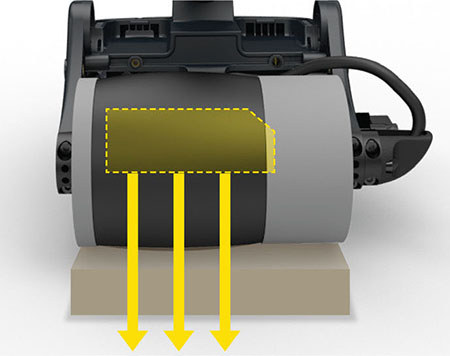

Loaded with the best of PA acoustic performance, a large 51.2mm active coverage (64E) and 25mm water path for typical T of 100mm in steel & 50mm in CFRP.

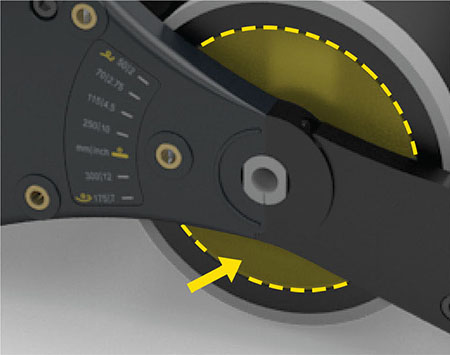

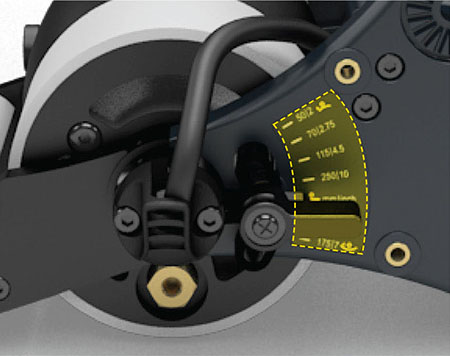

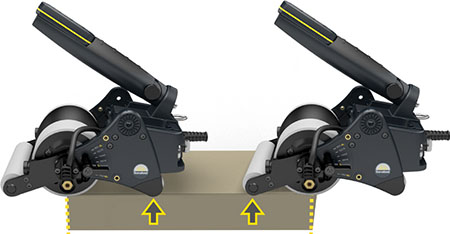

Curvature pointer is a flexible, quick and easy probe adjustment feature to match concave (min 175mm), flat or convex (min 50mm) surfaces.

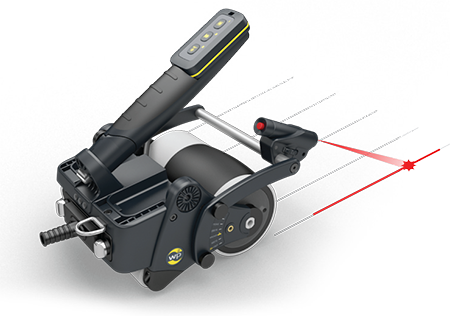

Accurate alignment with laser pointer

Scan edge to edge

WP2 allows you to build the most efficient solutions for scanning large areas of composite. As the best alternative to immersion inspection, the WP2 offers an impressive 1mm near surface resolution in the latest composite materials using 5MHz array. Available also with 10MHz, 3.5MHz and 2MHz versions, the WP2 tightly matches the acoustic impedance of water and like its predecessor, generates UT signals of exceptional quality. The configurable handles, adjustable laser guidance, unique LED’s for alarm feedback, remote control with start/stop indexing and reset buttons as well as the remote display makes this package unique, superior and still unequaled.

Recommended Kit for Composite

Precision Rollers

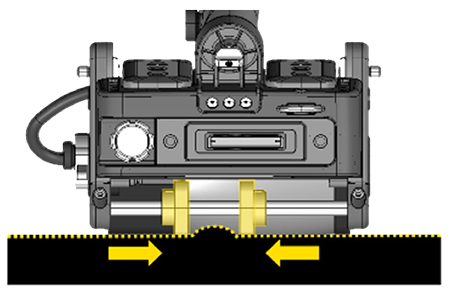

Axial Scanning

Making complete and reliable surveys to generate corrosion maps is essential. With the efficiency, performance and precision provided by the WP2, it is now possible to inspect large areas and quickly analyze data to determine if any critical or urgent action is required. Moreover, this technique allows the user to compare large amounts of data over time to perform preventative maintenance, reducing potential downtime. With WP2 the level of confidence is significantly increased since decisions can be based on data sets that are 1000 times more detailed, yet still gathered in the same time needed to do ‘spot checks’ using traditional methods. Whether for axial or longitudinal inspection using unique grooved rollers or attached to a scanner, WP2’s flexibility makes it the tool of choice for fast and accurate corrosion monitoring applications.

Recommended Kit for Corrosion

| Weight | 2.34 lbs. (1.06 kg) |

| Dimensions (HxLxW) | 4.9" x 5.9" x 6.1" (125 x 150 x 155 mm) |

| Operating Temperature | 50 to 122°F (10 to 50 °C) |

| Centre Frequency Options | 2 MHz, 3.5MHz, 5MHz and 10 MHz ±10% |

| Number of Elements | 64 |

| Total Active Length | 2" (51.1 mm) |

| Sensitivity Homogeneity | ± 3 db |

| Weight: | 2.34 lbs. (1.06 kg) |

| Dimensions (HxLxW) | 4.9" x 8.3" x 6.1" (125 x 211 x 155 mm) |

| Operating Temperature | 50 to 122°F (10 to 50 °C) |

| Centre Frequency Options | 1 MHz, 2MHz, 3.5MHz, 5MHz and 10MHz |

| Number of Elements | 128 (102 for 1 MHz) |

| Total Active Length | 4" (102.2mm) |

| Sensitivity Homogeneity | ± 3 db |

| Description | WP2 64 Element | WP2 128 Element |

| WP2-5M128/64E-0.8x6.4 | WP2-0501 | WP2-0601 |

| WP2-10M128/64E-0.8x6.4 | WP2-0502 | WP2-0602 |

| WP2-2M128/64E-0.8X6.4 | WP2-0503 | WP2-0603 |

| WP2-3.5M128/64E-0.8X6.4 | WP2-0504 | WP2-0604 |

| WP2-1MHz102E-1.0x6.4 | N/A | WP2-0605 |

Purchase Includes:

| Description | Order No: |

|---|---|

| Spray Bottle | 195180 |

| Pump syringe nozzle | 152005 |

| Polyhib additive 125ml | N/A |

| Storm case | WP3-ACC-0716 |

| USB Manual | 147417 |

| Maintenance tool | WP2-TOOL |

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| Sonatest WP2 Wheel Probe 2 - 64 Element | UT-ST-WP2-64 |

|

Request Pricing | ||

| Sonatest WP2 Wheel Probe 2 - 128 Element | UT-ST-WP2-128 |

|

Request Pricing | ||