| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| Dolphitech Dolphicam2 User Friendly Ultrasonic Imaging System | UT-DOL-DOLPHICAM2 |

|

Request Pricing | ||

Dolphitech’s flagship ultrasonic technology platform, the Dolphicam2, is the result of more than 10 years of dedicated research into Ultrasonics and represents the leading standard for volumetric NDT. The Dolphicam2 is capable of high resolution imaging and precise measurements for a wide range of material types including composites, metals, multi materials and more. With a straightforward, quick to deploy, user-friendly system, technicians of all experience levels can generate analysis-ready images of materials in real time for quick decision making.

Features:

Applications:

For Inspecting:

Use the chart below to see if the Dolphicam2 can perform inspections on materials relevant to your application.

| Kevlar | HDPE | ECR Glass for FRP Piping | Resins and Epoxies | Coatings | |

| Thickness | √ | √ | √ | √ | √ |

| Delamination | √ | √ | √ | √ | |

| Debonding | √ | √ | √ | √ | √ |

| Bondline Measurement | √ | ||||

| Porosity | √ | √ | |||

| Voids | √ | √ | √ | ||

| Hardness Testing | √ | ||||

| Corrosion / Erosion | √ | ||||

| Cracking | √ |

How does it work?

Dolphitech uses a unique 2D matrix array architecture to produce a transducer module (TRM) with 16,384 elements and an active aperture of 32x32mm. This is achieved using 128 transmitting electrodes which are positioned across 128 receiving electrodes, with each crossing point forming an individual element with a pitch of 0.25mm. This provides unparalleled data capture and resolution, which, when combined with our frequency range from 1.5MHz to 10MHz, gives you the ability to inspect a wide range of materials.

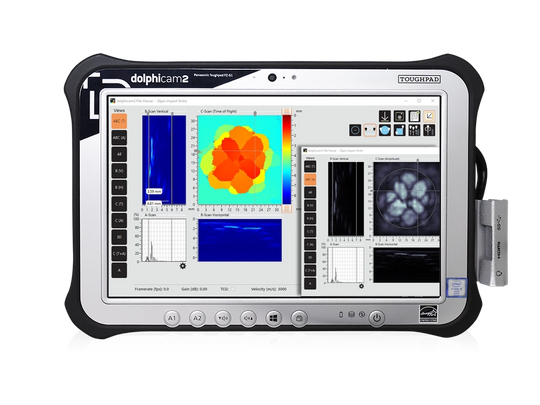

What's on the screen?

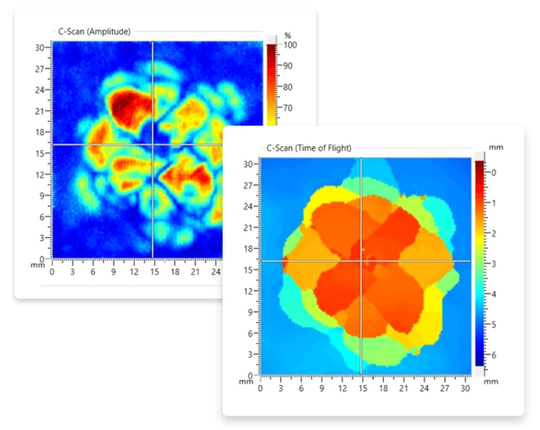

The dolphicam2 software is unique among NDT packages, designed from the ground up to complement the imaging capabilities of the platform. Ultrasonic images are shown not just using conventional signal amplitudes, but also as time of flight, opening up a world of instant, color-coded thickness mapping. This is helped further by the live 3D views, which instantly enhance visualization and can be readily interpreted by non-specialists. For maximum image quality we also provide Total Focusing Method (TFM) reconstructions, with TFM images accessible both during the acquisition itself, and on previously acquired Full Matrix Capture (FMC) data files.

What's in the box?

Dolphicam2 comes in a custom Pelicase with the chosen TRM(s), a connected Blackbox, and a Panasonic Toughpad. The TRM includes not just the transducer itself, but the Analogue to Digital Convert (ADC) electronics. This means that it connects to the Blackbox via a simple USB-C cable, removing the need for bulky multipin cables and plugs. The Blackbox itself is the heart of the system, driving the TRM while connecting to the Toughpad which runs and displays the software. The Blackbox and Toughpad are joined by a sturdy frame, and the whole system is reinforced to withstand daily site use.

What’s the learning curve?

With 16,384 elements, you might think that the power of the Dolphicam2 is difficult to harness. With the carefully designed user interface, this couldn’t be further from the truth. The system itself does the heavy lifting and lets the operator focus on the data generated. The Dolphicam2 can be setup in 60 seconds, and new users without specialist NDT knowledge can be up and scanning within hours. To help users get the most out of their system, Dolphitech run a range of training courses that are tailored to users’ inspection needs and prior NDT knowledge.

How will it perform on site?

Weighing in at ~7 lbs (3kg) for the whole system, the Dolphicam2 is easily portable. Combined with a continuous use battery life of 5-6 hours, this makes it well-suited to life on site. Useful features include integrated neck strap, corner bumpers, plug protection shields and an IP66 ingress protection rating. All of this and an operational temperature range of -4° to +50° F (-20 to +50°C) means that the Dolphicam2 can be relied on for routine use in both indoor and outdoor industrial settings.

The Dolphicam2 has 6 available transducers to choose from. Each has their own recommended use and pertinent case study.

See below for more details.

TRM 1.5 MHZ Probe

The 1.5MHz transducer module (TRM) is currently our lowest frequency on offer, and is designed for maximum penetration of thick GFRP and thick, out-of-autoclave CFRP with porosity. For more details, click the links below:

TRM 2.5 MHZ Probe

The 2.5 MHz transducer module (TRM) is well-suited to thicker section and lower grade composite material inspection. These include GFRP, out-of-autoclave CFRP as well as thick, coarse-grained metals. For more details, click the links below:

TRM 3.5 MHZ Probe

The 3.5 MHz transducer module (TRM) is an excellent choice for CFRP applications, as the frequency is low enough to travel through CFRP but still high enough to get a great resolution on your inspection. For more details, click the links below:

TRM 5 MHZ Probe

The 5 MHz Transducer module (TRM) sits at the middle of our range and is a fantastic all-rounder, well-suited to both metallic and composite applications. It provides superior resolution while maintaining good penetration through a wide variety of materials. For more details, click the links below:

TRM 8 MHZ Probe

The 8 MHz transducer module (TRM) is a great choice for a wide range of metallic applications. This frequency provides high resolution for great sensitivity, while also providing enough penetration for fine grained metal. For more details, click the links below:

TRM 10 MHZ Probe

The 10MHz transducer module (TRM) is our highest frequency model and provides great sensitivity for inspections of thinner components. The short wavelengths generated by this TRM provide high spatial resolution through the depth of the component. For more details, click the links below:

The Dolphicam2 can also be used with 7 different Delay Lines, for use with different transducers. See below for details.

Delay Line Aqualene 320 8mm

Detachable Delay Line that can be used with the following transducers: TRM-EA-1.50MHz, TRM-BE-2.50MHz, TRM-AE-3.50MHz, TRM-CH-6.00MHz, TRM-DD-8.00MHz, TRM-DC-10.00MHz. Bracket Included. For more details, click the links below:

Delay Line Aqualene 320 12mm

Detachable Delay Line that can be used with the following transducers: TRM-EA-1.50MHz, TRM-BE-2.50MHz, TRM-AE-3.50MHz, TRM-CH-6.00MHz, TRM-DD-8.00MHz, TRM-DC-10.00MHz. Bracket Included. For more details, click the links below:

Delay Line Rexolite 8mm

Detachable Delay Line that can be used with the following transducers: TRM-EA-1.50MHz, TRM-BE-2.50MHz, TRM-AE-3.50MHz, TRM-CH-6.00MHz, TRM-DD-8.00MHz, TRM-DC-10.00MHz. Bracket Included. For more details, click the links below:

Delay Line Rexolite 12mm

Detachable Delay Line that can be used with the following transducers: TRM-EA-1.50MHz, TRM-BE-2.50MHz, TRM-AE-3.50MHz, TRM-CH-6.00MHz, TRM-DD-8.00MHz, TRM-DC-10.00MHz. Bracket Included. For more details, click the links below:

Delay Line Rexolite Flat

Replaceable Pipe Shoe or Delay Line that is good to use to inspect Glass fiber or Carbon fiber. Compatible with transducers TRM-EA-1.50MHz, TRM-BE-2.50MHz and TRM-AE-3.50MHz. Bracket included. For more details, click the links below:

Curved Delay Line - Water Nozzle

Hard delay line for curved applications, delivered in 2"/50mm, 4"/100mm, 8"/200mm, 12"/300mm and 24"/600mm. This Rexolite delay line is easily grinded/sanded to fit the application. It is prepared for water/couplant nozzle. For more details, click the links below:

Hard Curved Delay Line - Rexolite

Hard delay line for curved applications, delivered in 2"/50mm, 4"/100mm, 8"/200mm, 12"/300mm and 24"/600mm. This Rexolite delay line is easily grinded/sanded to fit the application. It is prepared for water/couplant nozzle. For more details, click the links below:

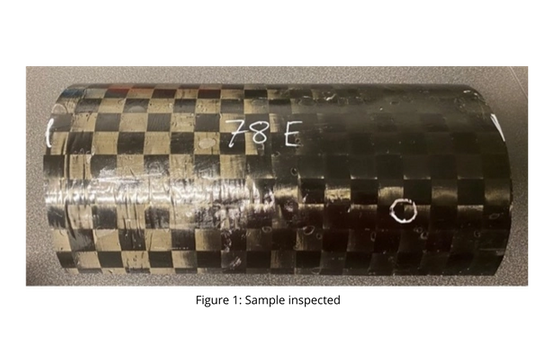

Woven Composite Panel

Carbon Fiber Reinforced Polymer. Conclusion: A TRM-DB-8MHz is well-suited to inspection of thin, woven CFRP laminates, typical in automotive and aerospace applications.

Wind Turbine Blade GFRP

Glass Fiber Reinforced Polymer. Conclusion: A TRM-EA-1.5MHz is well-suited for the inspection of thick wind blade GFRP. In this study, wind turbine-specific panels were successfully inspected, with embedded defects easily resolved and color-coded for straightforward analysis.

Composite Material from a Leading Manufacturer

The dolphicam2 with a TRM-CH-5MHz and a 200mm curved pipe shoe was able to inspect the pipe section provided. Using a manual stitching technique, an overall appraisal of the condition of the pipe section was obtained, with precise location of any defects. Then by acquiring a single image capture at the location of a defect observed, a large amount of quantitative information was gained for complete characterization.

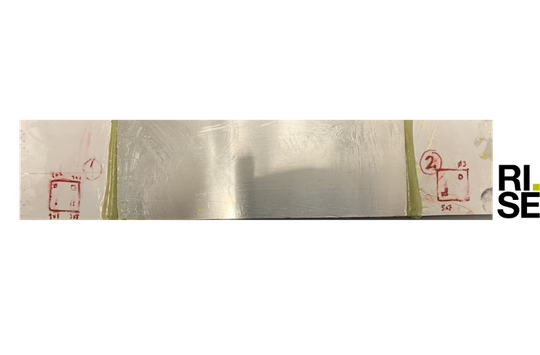

Adhesive Bonding of Thin Metals

Conclusion: The dolphicam2 was able to successfully resolve small reflectors within an adhesive bonding layer between two metal sheets. In addition, the ability of the dolphicam2 to resolve different general back surface contact conditions was also highlighted. This result demonstrates the versatility of the dolphicam2 with the 8MHz TRM, which is also well-suited to inspection of thin composites.

Pitting Corrosion in Stainless Steel

Conclusion: The dolphicam2 with the TRM-DA-10.00MHz proved well-suited to this challenging inspection of pitting corrosion in stainless steel. Through combining our powerful core TRM technology with an intuitive set of live image displays, complex inspections become easy to interpret.

Unrivaled Ultrasonic Inspection Results for Wind Blades

At both ends of the product life cycle, Dolphitech products enable a greater understanding of what’s happening inside materials. Conclusion: the Dolphicam2 provided quantitative data for damaged areas of the blade, allowing engineers to assess whether to repair or replace the blade. Wind blade inspections were performed on-site and at height due to its portability and ease of use.

GRP Pipe Sections

Glass Reinforced Plastic. Conclusion: A TRM-EA-1.5MHz is well-suited to a variety of GRP pipe inspections. Although capable of penetrating up to 60mm, good results were achieved at thicknesses down to 6mm in this study. This illustrates the wide range of GRP thicknesses and diameters that can be inspected using this versatile set up.

Impact Damage to an Aircraft

Carbon Fiber Reinforced Plastic. Conclusion: the Dolphicam2 provided quantitative data for damaged areas of the sample, allowing engineers to assess whether to ground the aircraft or release it for flight operations. Aircraft inspections have been carried out on the tarmac on other occasions with success, due to portability and ease of use. Thanks to our non-destructive evaluation, data was quickly uploaded and shared with experts both at the client’s main maintenance facilities, in addition to the aircraft manufacturer’s engineers for post processing and deeper analysis.

Monolithic CFRP Step Block

Carbon Fiber Reinforced Polymer. Conclusion: The dolphicam2 with the 3.5MHz TRM was able to penetrate the full 16mm thickness of the CFRP step block, and resolve most of the flat bottomed holes, with real-time, color-coded interpretation of their depth.

A220 Wing Skin Example

20mm thick Carbon Fiber Reinforced Plastic. Conclusion: The dolphicam2 was able to fully penetrate the material, identifying the area with the indication, even through the copper mesh.

Water Ingress

Aluminum Honeycomb Panels. Conclusion: Dolphicam2 is especially well suited for this application, as it has the necessary sensitivity, ease of use and quick set up. The standalone 1.4 software also allows inspections to be conducted by less experienced technicians, data can then be analyzed remotely anywhere in the world; saving on both the amount of time and the amount of analysis expertise required on-site, as well as the need for NDT experts to travel to site.

Adhesive Joint Inspection

Two 0.8mm steel plates glued together. Conclusion: A wide gate was set around several echoes in the plate (you can view the gate in B-scan in pictures below) The “Jet” color palette was used and compressed, to obtain stronger color contrast in the C-scan ultrasound image.

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| Dolphitech Dolphicam2 User Friendly Ultrasonic Imaging System | UT-DOL-DOLPHICAM2 |

|

Request Pricing | ||