The D2S scanner is a dual-channel dryer scanning system designed to meet the unique requirements of ultrasonic inspection on cast iron paper machine dryer rolls. The system is user-friendly and provides a wide range of automated capabilities. Dryer calibration is made simple by the addition of step-by-step instructions to guide the user through the process. Automated data acquisition and reporting is also available for several additional types of scans. Graphical printouts of the scan data and dryer roll information are sent to the default printer with just a click of a button. The D2S system is built upon the Analyst X software and data acquisition system. This allows for the system to be configured to also perform conventional B-scans with a minimal amount of additional components. Analyst X D2S offers the best dryer roll inspection system available.

Automated calibration

Reduced zero error

Fast inspection rates

Easily viewable A-scan display

Independent gain and frequency settings

Access to time-of-flight data

Ability to re-gate data

Reliable trending

Real-time view of thickness profile

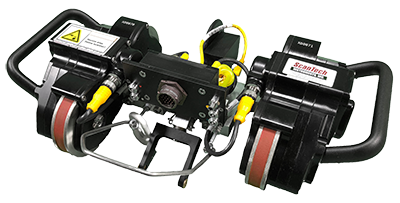

The X2 Spider is a remote scanner that is designed to work in conjunction with the D2S software. The scanner is capable of ultrasonic corrosion inspection for dryer rolls, tanks, pipes, and vessels. The parts are machined from billet 6061 Aluminum and 303 stainless steel with strategic cavities for weight reduction. This combination provides a durable yet agile crawler.

The X2 is a highly maneuverable system and is capable of traversing difficult obstructions made possible by the high suspension compliance. It is designed with a proprietary direct drive gear set and does not use any belts, chains, set screws, or clamps, which eliminates slippage. The scanner utilizes rare earth motors with the highest power density available to provide a high performing crawler. The unit is completely sealed from the environment and has a hard coat anodized exterior to reduce environmental wear on the system. Each scanner is manufactured in-house and is rigorously tested, so you can trust that the scanner you receive is of the highest quality.

The ScanTech Analyst X software powers the D2S system. This powerful software, achieved by rigorous product engineering, makes performance and repeatability easier to attain. Real world conditions are always a factor in the effort to maintain the latest standards of the industry. Overcoming these conditions and limitations drive the continual research from the ScanTech team to make a quality product for your scanning needs.

X2 Spider Scanner

X Controller/UT Instrument with Touch Screen

Analyst X B-Scan Software

Analyst X D2S Add-in

Main Cable Assembly, 55 ft. (16 m)

Rugged Transport Case (x3)

Joystick Assembly (X-Series)

Joystick Cable 50 ft. (15 m)

D2S Dual-Channel Transducer

WS3 Couplant Delivery System

Tool kit

Spare parts kit

Notebook PC and Case

Wedge Adapter Bracket

D2S Calibration Blocks (Brass and Carbon Steel)

D2S Wedge Jumper Cable

BPS Battery Pack

Yankee Blocks (Brass and Carbon)

Main Cable Assembly, 100 ft. (30 m)