| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

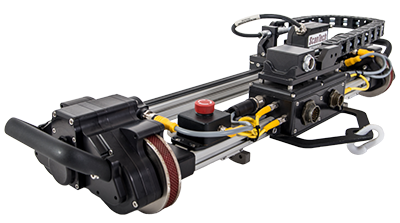

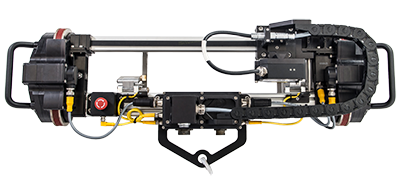

| ScanTech XR Spider Corrosion Mapping Scanner | RT-SCT-XR-SPIDER |

|

Request Pricing | ||

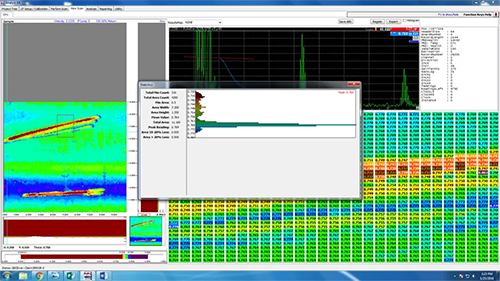

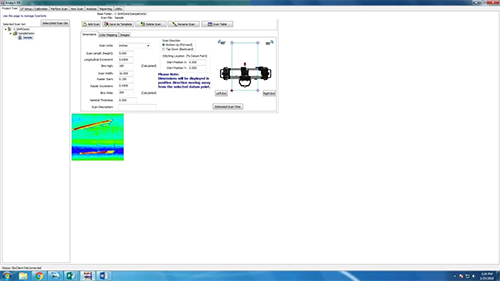

The XR Spider is an innovative ultrasonic scanner designed for automated raster scanning. Known for its high performance, durability, and maneuverability, the XR Spider is engineered to handle diverse industrial applications with ease and precision. The scanner traverses large vessels with obstacles that are problematic for most tank crawlers. It is capable of performing corrosion scanning on pipes as small as 2” while requiring no probe adjustments over the range. The scanner offers high maneuverability via steering with the controller’s touch screen interface or optional extended joystick and achieves high speeds without sacrificing torque and actuator force.

| Scanner Specifications | |

| Scan Arm Lengths: | 12", 24", 34", 48" (300, 600, 870, 1200 mm) |

| Over-Travel: | Approx. 1" per side (25 mm per side) |

| Scan Limit Protection: | Homing Routine |

| Wheel Diameter: | 3.625" (92 mm) |

| Magnetic Pull Force: | 65 lbf per wheel (286 N), 260 lbf total |

| Scanner Weight: | 27 lbs. (12.2 kg) for 12" Travel, 29 lbs. (13.2 kg) for 24" Travel |

| Dimensions (24" Travel): | 4.5" x 9.25" x 44" (11.5 x 23.5 x 112 cm) |

| Standard Transducer: | Single element with water column or dual element with contact |

| Shoe Compliance: | 10° Drive Axis, 8° Scan Axis, 1.75" vertical (45 mm) |

| Probe Angle Adjustments: | None Required |

| Minimum Diameters: | Circumferential Diameter: 2" (63.5 mm) |

| Axial Scan: 12" Model: 16 ft. Diameter; 24" Model: 24 ft. Diameter | |

| Steering: | Yes |

| Sealed Enclosure: | Yes |

| Scan Axis Specifications | |

| Speed: | 13 in/sec (330 mm/sec) |

| Torque (Per Drive Section): | 74 in./lbs. (9 Nm) |

| Encoder Resolution: | 3,081.767 cts/in (121.3 cts/mm) |

| Controller Specifications | |

| Power Requirement: | 90-240 VAC or 23-24 VDC Battery Option |

| Inputs: | Remote joystick cable (optional), Cat6 Ethernet cable |

| Outputs: | Scanner control, Scanner Power, Positional Encoder |

| Scan Plan Input / Diagnostic Indicators: | Controller |

| Scan Rates | ||

| 1 m x 300 mm | 1 m x 600 mm | |

| 10 x 10 mm | 1:11 min. | 1:55 min. |

| 5 x 5 mm | 2:15 min. | 3:30 min. |

| 2 x 2 mm | 5:21 min. | 8:35 min. |

| 1 x 1 mm | 10:36 min. | 16:47 min. |

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| ScanTech XR Spider Corrosion Mapping Scanner | RT-SCT-XR-SPIDER |

|

Request Pricing | ||