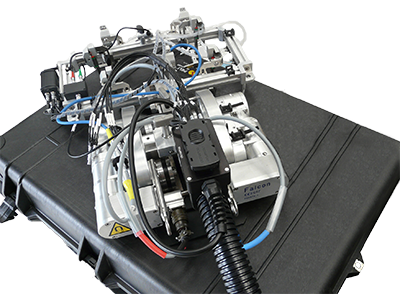

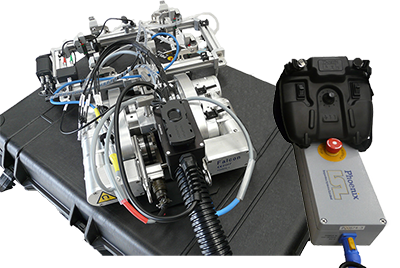

The Falcon is a powerful, magnetically attached 4×4 wheel drive scanner designed for single-axis weld inspection with conventional UT (TOFD/pulse-echo) and phased array (PAUT) or eddy current array (ECA) probes. The Falcon comprises two mutually articulated magnetic wheeled modules, each powered by a high-torque DC servo motor. A chain-driven, four-wheel drive system allows the scanner to maneuver over surfaces, overcoming obstacles such as weld caps. An articulated joint between the modules helps all four wheels maintain contact on curved surfaces, as the scanner is steered or rotated. A closed-loop servo system provides velocity control of the two motors ensuring smooth operation of the Falcon. The feedback control ensures the output speed of the scanner remains constant, regardless of orientation or drive direction, while the remote control feature uses thumbwheel joysticks providing skid steer motion, allowing for fine adjustments of each motor's speed for precise steering. The Falcon is a precision automated inspection solution supporting productivity and accuracy while reducing risk and inspection time.

| Range: | Minimum pipe size 1.5m up to Flat |

| Speed: | Maximum 35mm/s, Minimum 5mm/s |

| Total weight: | 33 lbs. (15kg) (includes transducer frame) |

| Dimensions (L x W): | 16" x 12" (415mm x 310mm) (Scanner Body) |

| 36" x 17" (920 x 430mm) (Overall including Scanner, Transducer Frame, Umbilical Clamp & Pre-Amp) | |

| Radial working clearance: | 10" (250mm) |

| Payload: | 22 lbs. (10kg) |

| Motor Power: | 80 watt |

| Motor Voltage: |

24 Volt |

| Operational Temperature Range: | 32° to 122°F (0° to 50°C) |

| Operational Humidity Range: | 0% – 100%RH |

For more information on purchasing this item, click on the link below.