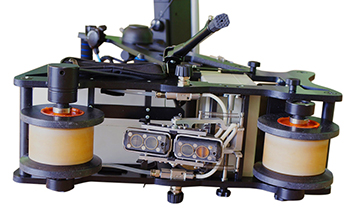

OKOndt UDS2-77 BASIC

Basic Ultrasonic Rail Flaw Detector

with A & B Scan displays

The UDS2-77-BASIC is a simplified version of the UDS-2-77-AREMA.

It has 5 probes: 2-45* degree, 2-70 degree and one 0 degree probe as shown below.

UDS2-77-BASIC ultrasonic rail flaw detector is intended for defect detection in rail along the running surface and rail cross-section, except for the rail foot flanges. It can also be used for manual check testing of welded joints and evaluation of detected defects. Test results are stored in non-volatile memory.

| |

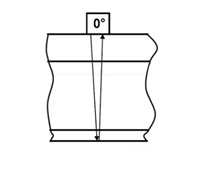

- HORIZONTAL CRACKING OF THE RAIL HEAD – 0° probe

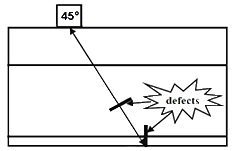

- VERTICAL CRACKING OF THE RAIL HEAD – 0° probe and 45° probe (in case of the crack location in the web projection);

- SHELLING OF RUNNING SURFACE – 0° probe

- HORIZONTAL CRACKING AT THE WEB-HEAD FILLET RADIUS – 0° probe

- HORIZONTAL CRACKING AT THE WEB-FOOT FILLET RADIUS – code 0° probe

- LONGITUDINAL VERTICAL CRACKING (PIPING) – 0° probe and 45° probe

- STAR-CRACKING OF FISHBOLT HOLES – 0° probe and 45° probe

- DIAGONAL CRACKING AWAY FROM ANY HOLE – 0° probe and 45° probe

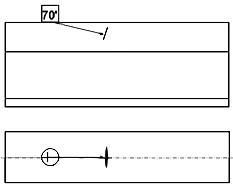

- PROGRESSIVE TRANSVERSE CRACKING (KIDNEY-SHAPED FATIGUE CRACK) – 70° probe

- HORIZONTAL CRACKING – 0° probe and 45° probe

|

|

|

| A-Scan Mode |

B-Scan Mode |