| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| UDS2-77 Ultrasonic Rail Flaw Detector | UT-OKO-UDS2-77 |

|

Request Pricing | ||

The UDS2-77 ultrasonic single rail flaw detector is a handpush cart intended for the inspection of one rail line. The product is manufactured in nine modifications and can employ either a Slide Search Unit or Roller Search Unit, and contains from 3 to 13 UT probes. The UDS2-77 rail flaw detector employs a unique scanning scheme that allows testing of an entire rail section (except for the rail base) using pulse echo, echo-shadow and echo-image techniques. Both mechanics (the cart) and electronics (the software) of the UDS2-77 are ergonomically designed, have a user-friendly intuitive interface, as well as they are resistant to severe weather conditions that may occur during operation on a railroad.

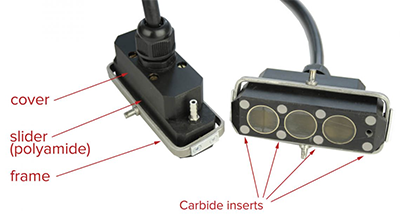

The UDS2-77 flaw detector employs contact probe units of conventional type with both standard and specialized probes. The probe units are made from wear resistant plastic material, with hard-metal inserts on the working surface.

Probe Unit No. 1:

Probe Unit No. 2:

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| UDS2-77 Ultrasonic Rail Flaw Detector | UT-OKO-UDS2-77 |

|

Request Pricing | ||