| Measurement Modes |

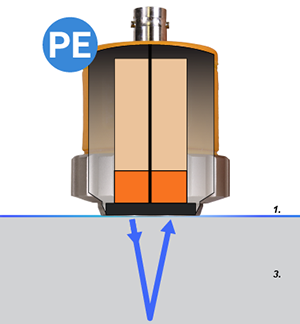

| Pulse-Echo (P-E): Contact transducers |

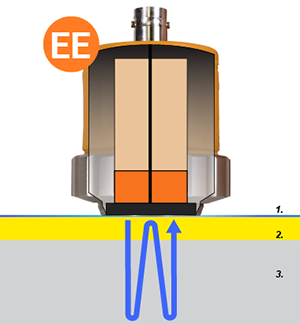

| Echo-Echo (E-E): Contact transducers |

| Echo-Echo Verify (E-EV): Contact transducers. |

Pulser:

Spike - 200 volt adjustable.

Square wave: 400 volt adjustable.

Tone Burst: 400 volt adjustable with selectable frequency. |

| Receiver: Manual or AGC gain control with 110dB range, varies with mode selected. Adjustable damping (50, 75, 100, 300, 600 & 1500 ohms). |

| Frequency Range: 500 kHz to 10 MHz |

| Timing: Precision TCXO timing with single shot 100 MHz 8 bit ultra low power digitizer. |

| Measuring Range |

| Pulse-Echo Contact: Steel: .050 in. – 100.0 ft. (1.27 mm – 30.5 M). Composites: .100 in. – 5.00 in. (2.54 mm – 127 mm). |

| Echo-Echo Contact: Steel: .100–3.0 ft. (2.54–91.44 cm). |

| Echo-Echo Verify Contact: Steel: .100–6.0 in. (2.54–152.4 mm). |

Resolution (selectable):

+/- .01 inch (0.1 mm).

+/- .001 inch (0.01 mm). |

| Velocity Range: 0.0122 to 0.7300 inches/µs (309.88 to 18542 meters/sec) |

| Single and Two point calibration option, or selection of basic material types. |

| Units: Imperial & Metric |

| Display Views |

| A-Scan: Rectified +/- (flaw view) RF (full waveform view). Refresh rate at 25 Hz. |

| B-Scan: Time based cross section view. Display speed variable (10 to 200 readings per second). |

| Large Digits: Standard thickness view; Digit Height: 0.700 in (17.78 mm). |

| Scan Bar: Speed 10 Hz. Viewable in B-Scan and Large Digit views. |

| Bar Graph: Measurement stability. |

| Features |

| Setups: 64 custom user-defined setups. |

| Gates: 3 adjustable gates, depending on measure mode selected. |

| Alarm Mode: Set Hi and Lo tolerances with audible beeper and visual LEDs. |

| Scan Mode: Takes 250 readings per second and displays the minimum reading found when the transducer is removed. |

| Physical Attributes |

| Dimensions (WxHxD) : 2.5" x 6.5" x 1.24" (63.5 x 165 x 31.5mm) |

| Weight: 13.5 oz. (with batteries) |

| Keyboard: Membrane switch pad with twelve tactile keys. |

| Data Output: USB-C port. Windows® PC interface software. |

| Display: 1/8in VGA grayscale display (240 x 160 pixels); viewable area 2.4 x 1.8in (62 x 5.7mm); EL backlit (on/off/auto invert). |

| Operating Temperature: 14 to 140F (-10C to 60C) |

| Case: Extruded aluminum body with nickel-plated aluminum end caps (gasket sealed). |

| Power Source |

| Line Power: USB-C to PC or power outlet. |

Batteries: Three AA cells. Alkaline - 35 hrs., Nicad - 10 hrs. and NI-MH - 35hrs.

* Dependent on pulser & backlight settings |

| Auto power off if idle 5 minutes. |

| Battery status icon. |

| Memory |

| Log Formats: Grid (Alpha Numeric), or Sequential (Auto Identifier). |

| Capacity: 4 Gb internal SD card |

| Screen Capture: Bitmap graphic capture for quick documentation (.tif ). |

| OBSTRUCT to indicate inaccessible locations. |

| Certification |

| Factory calibration traceable to NIST & MILSTD-45662A. |

| Warranty |

| 2 yr. limited |