90° Angled & Interchangeable Cap Probe Configurations

The standard Probe designs listed below may not be suitable for every measurement. As such, there are 90° Angled Probes available and Probes with Interchangeable Caps.

The 90° Angled Probes are suited for harder to reach places such as near corners and edges.

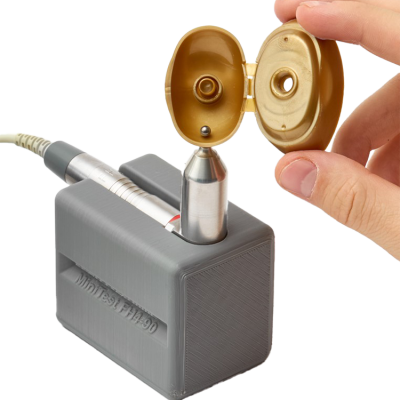

The Interchangeable Cap Probes features a replaceable metal cap for applications that require punctual positioning by hand and for measuring that will require more durable probes (such as in the instance of measuring with high impact intensity).

Most of the Probes listed below are available in either a 90° Angled Version or in an Interchangeable Cap Version. To see the full scope of available probes, see the Purchasing Guide here.

FH2 & FH2-M Probes

With its smaller design, the FH2 sensor type has been specially designed for measurement at measuring points that are difficult to access. In particular, measurements can be taken on small components or complexly shaped components with recesses, grooves, ridges and profiles with the help of the narrow and extended sensor tip. The slim sensor shape also greatly simplifies wall thickness measurement in the production and quality control of cosmetic containers, which often feature decorative structures or embossing.

| |

FH2 |

FH2-M (magnetic steel balls) |

| Diameter and type of reference ball: |

1.5 mm steel |

2.5 mm steel |

4.0 mm steel |

1.5 mm magnetic |

3.0 mm magnetic |

| Measuring uncertainty range: |

0 - 6.0 mm |

0 - 1.3 mm |

0 - 2.3 mm |

0 - 2.0 mm |

0 - 4.5 mm |

| Factory calibration: |

± (10 µm + 3 %) |

± (15 µm + 3 %) |

± (30 µm + 3 %) |

Magnetic Balls Require at least a zero calibration |

| Zero calibration: |

± (5 µm + 1.5 %) |

± (8 µm + 1.5 %) |

± (15 µm + 1.5 %) |

± (30 µm + 3 %) |

± (20 µm + 2 %) |

| Multiple point calibration: |

± (3 µm + 1 %) |

± (5 µm + 1 %) |

± (10 µm + 1 %) |

± (20 µm + 2 %) |

± (40 µm + 2 %) |

| Dimensions: |

Sensor length 4.17 in (105.9 mm) / Diameter 0.39 in (10 mm) |

FH4 & FH4-M Probes

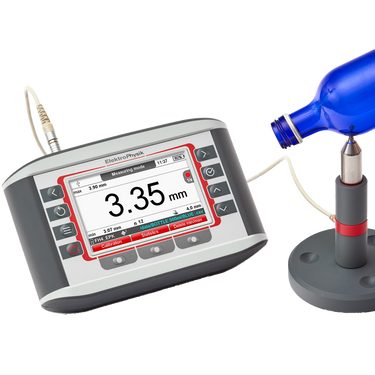

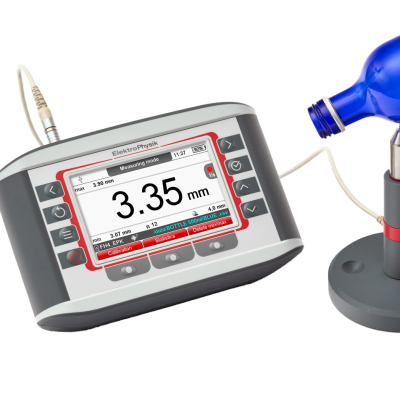

The FH4 sensor is the standard sensor for a wide range of applications in production and quality control: Wall thickness measurement of hollow bodies of all kinds, such as bottles, canisters, cosmetics containers, food packaging, non-ferritic components in the interior of automobiles or aircraft, tubes and hoses, composite components and much more.

For wall thicknesses exceeding 6 mm, magnetic reference balls can be used, which increase the measuring range up to 9 mm. In addition, the sensor is also available in a 90° angled version, in order to be able to measure points that are difficult to access or in the area of corners and angles and edges.

| |

FH 4 |

FH 4- M (magnetic steel balls) |

| Diameter and type of reference ball: |

1.5 mm steel |

2.5 mm steel |

4.0 mm steel |

1.5 mm magnetic |

3.0 mm magnetic |

| Measuring uncertainty range: |

0 - 2.0 mm |

0 - 3.0 mm |

0 - 6.0 mm |

0 - 5.0 mm |

0 - 9.0 mm |

| Factory calibration: |

± (10 µm + 3 %) |

± (15 µm + 3 %) |

± (30 µm + 3 %) |

Magnetic Balls Require at least a zero calibration |

| Zero calibration: |

± (5 µm + 1.5 %) |

± (8 µm + 1.5 %) |

± (15 µm + 1.5 %) |

± (30 µm + 3 %) |

± (20 µm + 2 %) |

| Multiple point calibration: |

± (3 µm + 1 %) |

± (5 µm + 1 %) |

± (10 µm + 1 %) |

± (60 µm + 3 %) |

± (40 µm + 2 %) |

| Dimensions: |

Sensor length 3.76 in (95.4 mm) / Diameter 0.67 in (16.9 mm) |

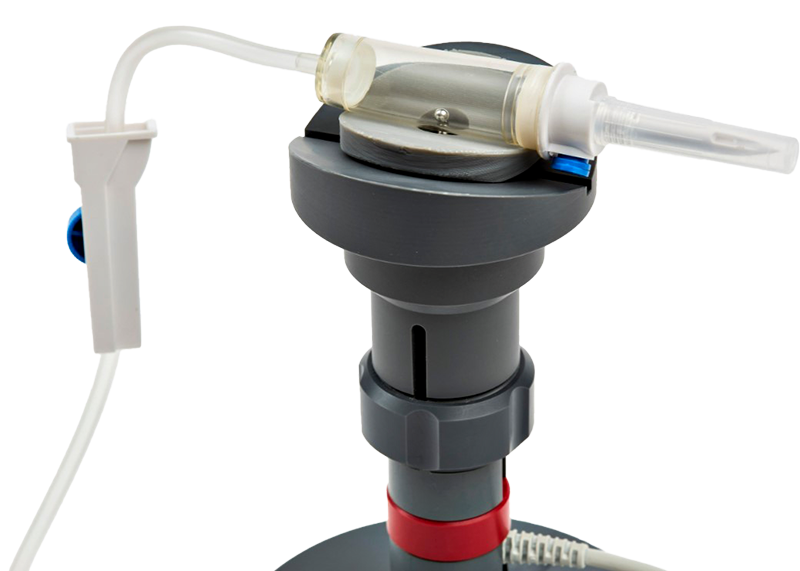

FH4-1 & FH4-Wire Probes

Beyond the standard applications, the FH4 sensor is available in special versions that have been modified for special measuring tasks. Especially in the medical sector, the measurement of small parts with often very narrow passage for the measuring balls is a frequent task, e.g. for the wall thickness measurement of tubes, artificial organs, stents, infusion sets etc. In these cases, the FH4-1 sensor type offers the possibility to measure wall thicknesses against a target ball of only 1 mm diameter. Other applications exclude the use of measuring balls due to the risk of non-recoverability in the object to be measured - here the FH sensor offers a special variant that measures against a measuring wire instead of a ball. The FH4-Wire sensor is indispensable for testing turbine blades where the wall thickness can be determined against a wire inserted into the cooling holes.

| |

FH4-1 |

FH4-WIRE |

| Diameter and type of reference ball: |

1.0 mm steel |

2.5 mm steel |

4.0 mm steel |

Target wire

ø 0.66 mm |

Target wire

ø 1.15 mm |

| Measuring uncertainty range: |

0 - 1.3 mm |

0 - 3.0 mm |

0 - 6.0 mm |

0 - 7.0 mm |

0 - 13.0 mm |

| Factory calibration: |

± (10 µm + 3%) |

± (15 µm + 3 %) |

± (30 µm + 3 %) |

± (10 µm + 3%) |

± (15 µm + 3%) |

| Zero calibration: |

± (5 µm + 1.5%) |

± (8 µm + 1.5 %) |

± (15 µm + 1.5 %) |

± (5 µm + 1.5%) |

± (8 µm + 1.5%) |

| Multiple point calibration: |

± (3 µm + 1 %) |

± (5 µm + 1 %) |

± (10 µm + 1 %) |

± (3 µm + 1%) |

± (5 µm + 1%) |

| Dimensions: |

Sensor length 3.76 in (95.4 mm) / Diameter 0.67 in (16.9 mm) |

FH10 & FH10-M

Testing of larger, lightweight components made of fiber composites such as GFRP and CFRP, which are used in mechanical engineering, automotive or aerospace, often requires the measurement of higher wall thickness. The standard version of the FH10 sensor offers a measuring range of up to 13mm, which the FH10-M sensor version can extend to 24mm using magnetic reference balls. Among others, the FH10 sensor is also indispensable for measuring the wall thickness of pipes and pipelines made of non-ferritic metals in pipeline construction as well as for the production of thick-walled glass bottles.

| |

FH10 |

FH10-M (magnetic steel balls) |

| Diameter and type of reference ball: |

2.5 mm steel |

4.0 mm steel |

6.0 mm steel |

4.0 mm magnetic |

6.0 mm magnetic |

| Measuring uncertainty range: |

0 - 4.0 mm |

0 - 7.0 mm |

0 - 7.0 mm |

0 - 16.0 mm |

0 - 24.0 mm |

| Factory calibration: |

± (15 µm + 3 %) |

± (30 µm + 3 %) |

± (50 µm + 3 %) |

Magnetic Balls Require at least a zero calibration |

| Zero calibration: |

± (8 µm + 1.5 %) |

± (15 µm + 1.5 %) |

± (30 µm + 1.5 %) |

± (60 µm + 3 %) |

± (80 µm + 3 %) |

| Multiple point calibration: |

± (5 µm + 1 %) |

± (10 µm + 1 %) |

± (20 µm + 1 %) |

± (60 µm + 2 %) |

± (60 µm + 2 %) |

| Dimensions: |

Sensor length 4.93 in (125.2 mm) / Diameter 1.15 in (29.2 mm) |