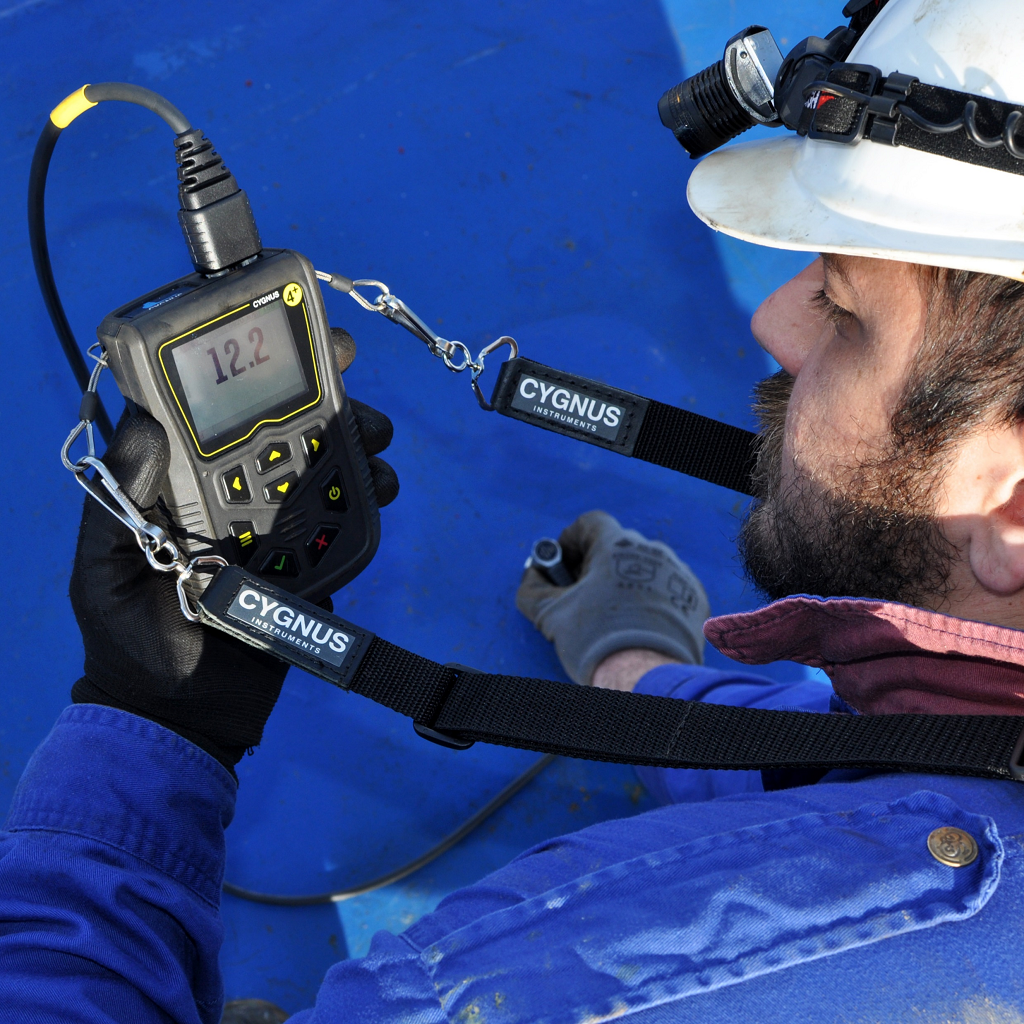

The Cygnus 4+ General Purpose Ultrasonic Thickness Gauge is a durable, high-performance inspection instrument engineered for multi-mode measurement versatility. Using Cygnus’s advanced Multiple-Echo technique, it enables precise thru-coating thickness readings without removing paint or protective layers. The device features a large, sunlight-readable color LCD with Live A-Scan display, data logging, and intuitive menus for efficient field operation. Designed for industries such as marine, oil & gas, power generation, and civil engineering, the Cygnus 4+ delivers accurate, repeatable results even on corroded or high-temperature surfaces, reducing downtime and improving inspection efficiency.

Multiple-Echo mode for accurate thru-coating thickness measurements without removing protective coatings, approved by Classification Societies

Echo-Echo and Single-Echo modes handle heavily corroded metals, thin coatings, plastics, and composites

Deep Coat function measures through coatings up to 0.8 inch (20 mm) thick

High-temperature capability — compatible with the Cygnus High Temp Probe for surfaces up to 572°F (300°C)

Live A-Scan display for real-time waveform verification

Automatic and manual gain control for measurement flexibility

Data logging of up to 5,000 measurements and A-scans per record, with auto-log and PDF report generation via CygLink software

Min/Max measurement limits with visual and vibration alerts

Shock and impact resistant to MIL-STD-810G standards

Water and dust tight to IP67 for reliable field performance

Safe for use in explosive atmospheres (Class I, Division 2, Group D locations per NFPA 70 Article 500)

Upgradeable design – field upgradable to Cygnus 6+ for expanded functionality

Ideal for oil and gas refineries and process plants requiring in-service, high-temperature thickness measurements

Used for ship hull, deck, and ballast tank surveys where thru-coating measurement is essential

Suited for pipes, tubes, and storage tanks in industrial maintenance and safety inspection programs

Commonly applied in civil engineering for assessing bridges, structural supports, and infrastructure components

Effective on heavily corroded metals and painted surfaces where coating removal is not practical

Excellent for general purpose ultrasonic testing across metals and engineering materials

| Cygnus 4+ General Purpose Ultrasonic Thickness Gauge Technical Specifications | |

|---|---|

| Measuring Modes: | Multiple-Echo – uses 3 echoes to ignore coatings up to 0.8 inch (20 mm) thick | Echo-Echo – uses 2 echoes to ignore coatings up to 0.04 inch (1 mm) thick | Single-Echo – uses 1 echo |

| Materials: | Velocities from 0.0390 – 0.3543 in/μs (1,000 – 9,000 m/s) |

| Accuracy: | ±0.002 inch (±0.05 mm) in Multiple-Echo mode | ±0.004 inch (±0.1 mm) or 0.1% of thickness in Single-Echo and Echo-Echo modes |

| Resolution: | Multiple-Echo – 0.005 inch (0.1 mm) or 0.002 inch (0.05 mm) | Single-Echo / Echo-Echo – 0.005 inch (0.1 mm) or 0.001 inch (0.01 mm) |

| Probe Options: | Single crystal, Twin crystal, and High temperature probes |

| Measurement Range in Steel: | 0.031 – 10 inch (0.8 – 250 mm), depending on probe and configuration |

| Connector: | 2 × Lemo 00 |

| Power: | 3 × AA / R6 batteries |

| Battery Life: | Approx. 10 hours continuous measurement |

| Electronics: | Dual channel pulser |

| Display: | 2.4 inch QVGA LCD (1.85 × 1.46 inch / 47 × 37 mm) |

| Size: | 3.3 × 5.1 × 1.4 inch (84 × 130 × 35 mm) |

| Weight: | 10.5 oz (300 g) including batteries |

| Operating Temperature: | 14°F to 122°F (–10°C to +50°C) |

| Data Logging: | 5,000 measurements and A-scans per record; up to 100 records (soft limit) |

| Computer Software: | CygLink – remote logging and A-scan viewing, PDF report generation, and statistical analysis |

| Environmental Rating: |

IP67 | Safe operation in Class I, Division 2, Group D locations per NFPA 70 Article 500 MIL-STD-810G Method 501.6 (high temp +131°F / +55°C) MIL-STD-810G Method 502.6 (low temp –4°F / –20°C) MIL-STD-810G Method 507.6 (humidity 95%) MIL-STD-810G Method 512.6 (immersion 3.3 ft / 1 m for 30 minutes) |

| Shock and Impact: |

MIL-STD-810G Method 514.7 (vibration) MIL-STD-810G Method 516.7 (shock 20 g, 11 ms half sine pulse) MIL-STD-810G Method 516.7 (transit drop 4 ft / 1.22 m) |

| Standards: | Designed for EN 15317 |

| Compliance: | CE, UKCA, RoHS |

| Warranty: | 3 years on gauge and 6 months on probe |

To purchase the Cygnus 4+ General Purpose Ultrasonic Thickness Gauge, click on the link