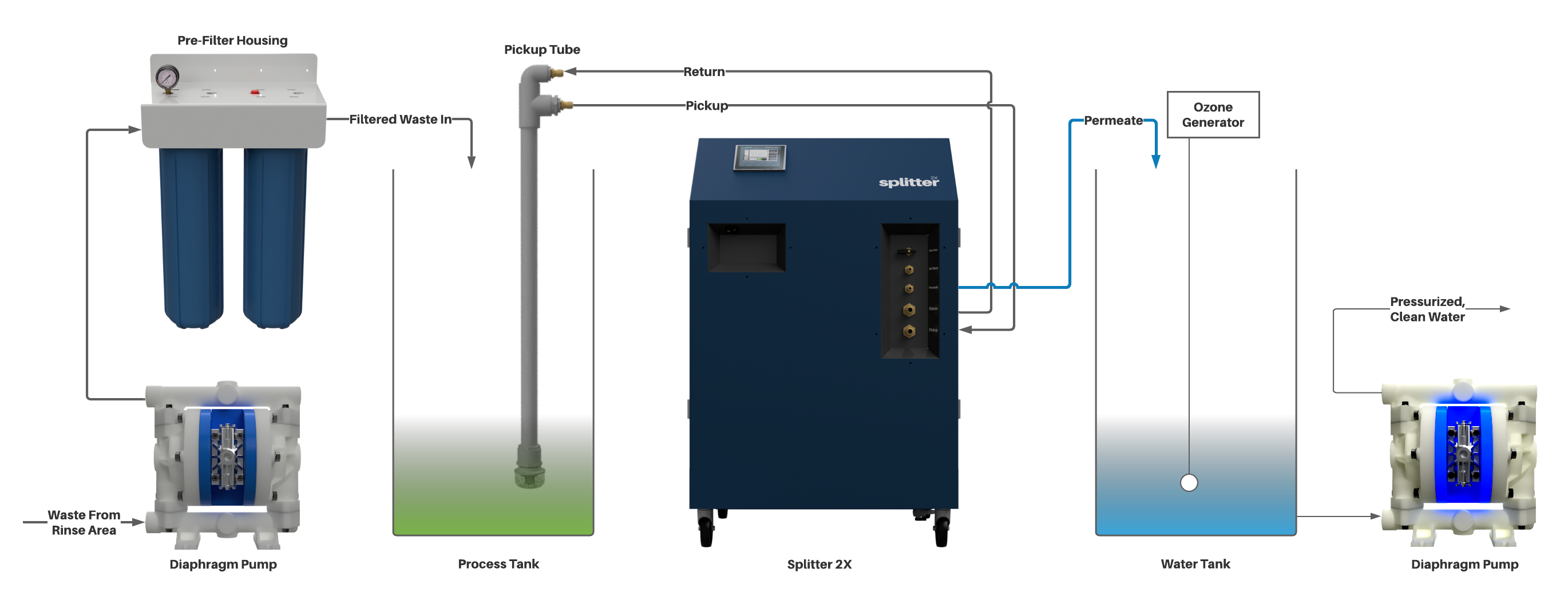

Splitter™ Series 2X and 4X Penetrant Waste Water Filtration Systems are the newest additions to the Infinitex - Splitter NDT family and on the cutting edge of filtration technology. The Splitter™ Series is the ideal liquid penetrant inspection station for the low to medium volume user. They are designed to run virtually on their own with a programmable logic controller that monitors and records a variety of factors, including pressure, temperature, time and maintenance. The Splitter™ series is now available in two configurations, the 2X and 4X, capable of handling a nominal volume of 200 gallons per day and 400 gallons per day of waste water, respectively.

Key Features:

Controls and Electrical Features:

Common Applications Include:

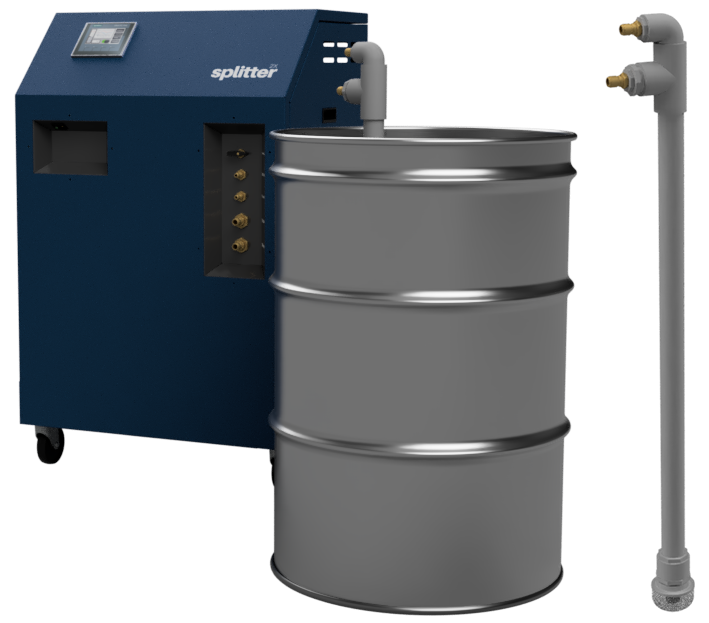

When purchasing this system, there is the option to supply your own holding tank. For small volume applications, a 55 gallon drum can be connected with the supplied pickup tube (included with purchase of a Splitter Series unit) that eliminates the need for plumbing to be added to the holding tank. Since the area at the bottom of a 55 gallon drum is fairly small, the need for a conical bottom is eliminated.

55 Gallon Drum Recommendations:

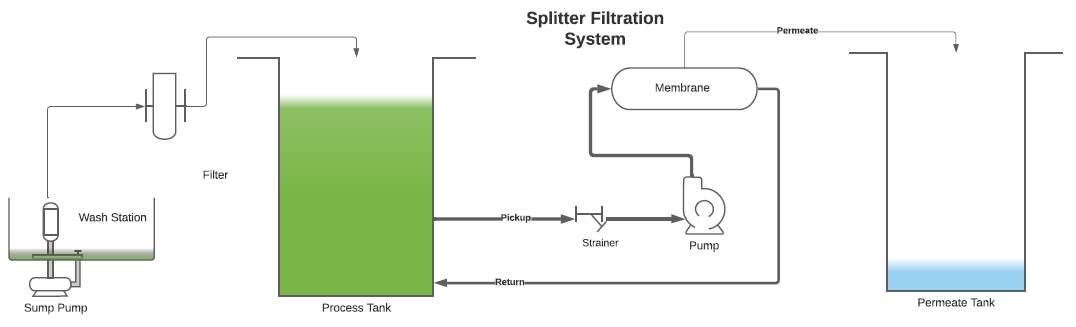

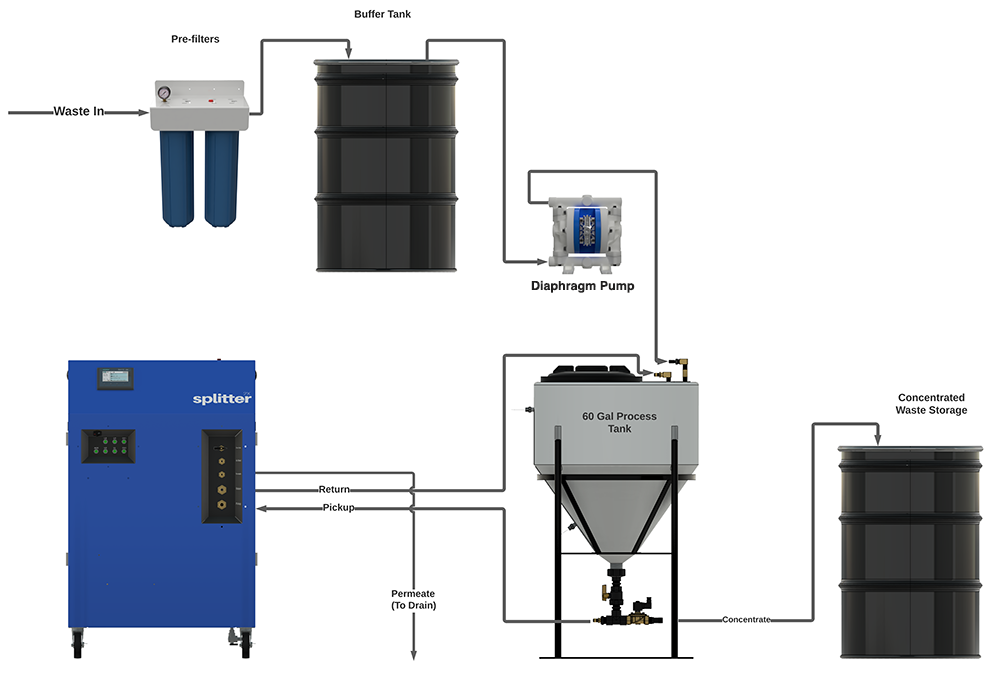

Waste is automatically transferred from Buffer Tank to Process Tank via diaphragm pump. Splitter will process the waste automatically and stop when waste is reduced to 10% of original volume (~6 gallons). Splitter will fully drain the concentrated waste via gravity (or optional pump) to the Concentrate Waste Storage Tank. This cycle will repeat until Buffer Tank is detected to be empty, or the Concentrate Waste Store drum is detected to be full.

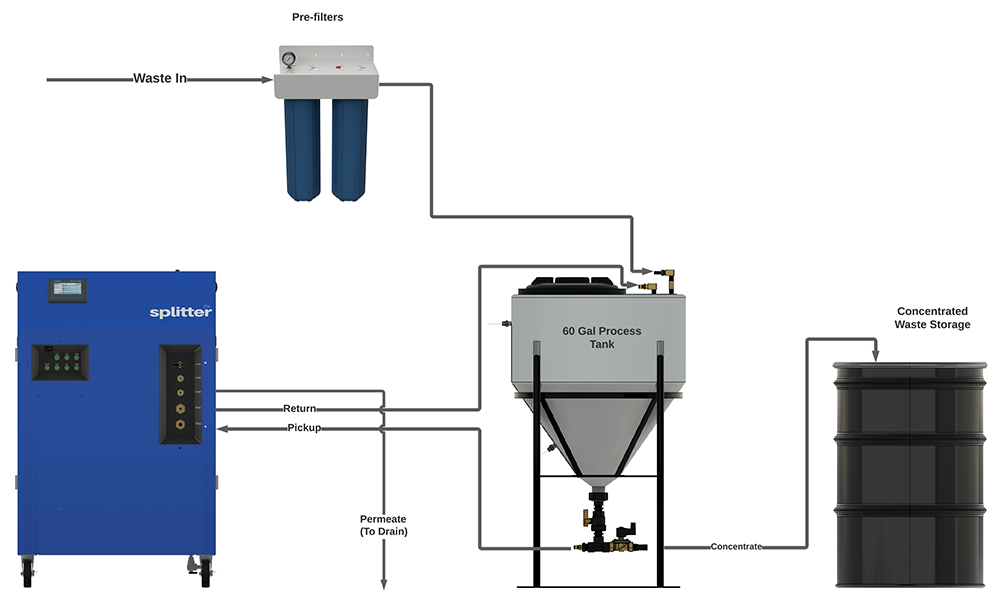

Waste is accumulated over the course of the week in the Process Tank. A Process cycle is manually started. Process will stop when waste is reduced to 10% of original volume (~6 gallons). The user can fully drain the concentrated waste via gravity (or optional pump) to the Concentrate Waste Storage Tank.

| Splitter™ Series Filtration Specifications | ||

| Spec. | Splitter™ 2X | Splitter™ 4X |

| Number of Membranes | 2 | 4 |

| Nominal Capacity with Nano Membranes | 200 Gallons per 24 hours | 400 Gallons per 24 hours |

| Dimensions | 22"L x 28"W x 45"H (55 x 70 x 115 cm) | |

| Weight | 185 lbs (84 kg) | 205 lbs (93 kg) |

| Membranes | "Nano (232)": 100-250 Da "Ultra (444)": 400k Da Other Custom Pore Sizes Available Upon Request |

|

| Material | Powder Coated Steel | |

| Installation Requirements | 120V, 15 Amp Power Flat, Level Ground Access to Clean Water |

|

| Features and Accessories |

Siemens PLC and HMI: Intuitive Controls, Digital Sensor Readout, Logging |

|

Process Tank should be emptied at the end of each batch. Membranes need to be cleaned once per week, or when the permeate rate falls 10 to 20 percent below the rate after the last cleaning cycle.

Completely dependent on the total volume (and size) of suspended solids present in the waste stream. Likely once per month, but it could range from few times a week to few times per year. Once a month is most likely.

Unacceptable low permeate rate, that will not increase after cleaning cycles. Low permeate quality (visibly discolored). On average, with proper maintenance and care, membranes should last 6-12 months.

The concentrate should be pumped out when 100 gallons of waste is reduced to 5-10 gallons.

Spun Polypropylene, 20 inches.

Our membranes can handle post-emulsifiable penetrants so long as there is no excess amount of emulsifier in the waste water.

Most are all standard Quick connects.

Yes, it has to get into the process tank in some way.

Nanos are tighter and are generally used for LPI applications only. The "Ultra" membranes are geared towards emulsified cutting oils, coolants, vacuum condensate, and mop water and general; waste applications. If there is a specific product in question, please contact us to discuss

Either process should have prefiltration, it will at least prefilter solids and some of the smaller contaminants. The downside is shorter membrane life.

No, they are sold separately in boxes of 4 and are relatively inexpensive to the membranes

Prior to entering the process tank.

Yes, as this is a batch process and you can actually hold as much of the waste in a process or holding tank as you want. However, the idea is to match up as closely as possible the amount of waste per day and then the pumping/dumping of the concentrate.

About 6-7 hours with the Splitter 2X and 3-4 hours with the 4X. These are estimated figures.

Continuously running for 24 hours will consume about 30-35 kWh. Multiply this by your customer's electric rate to get the cost of operating.

For reference, running this machine in the Splitter office would cost about $3-$4 (USD) per day

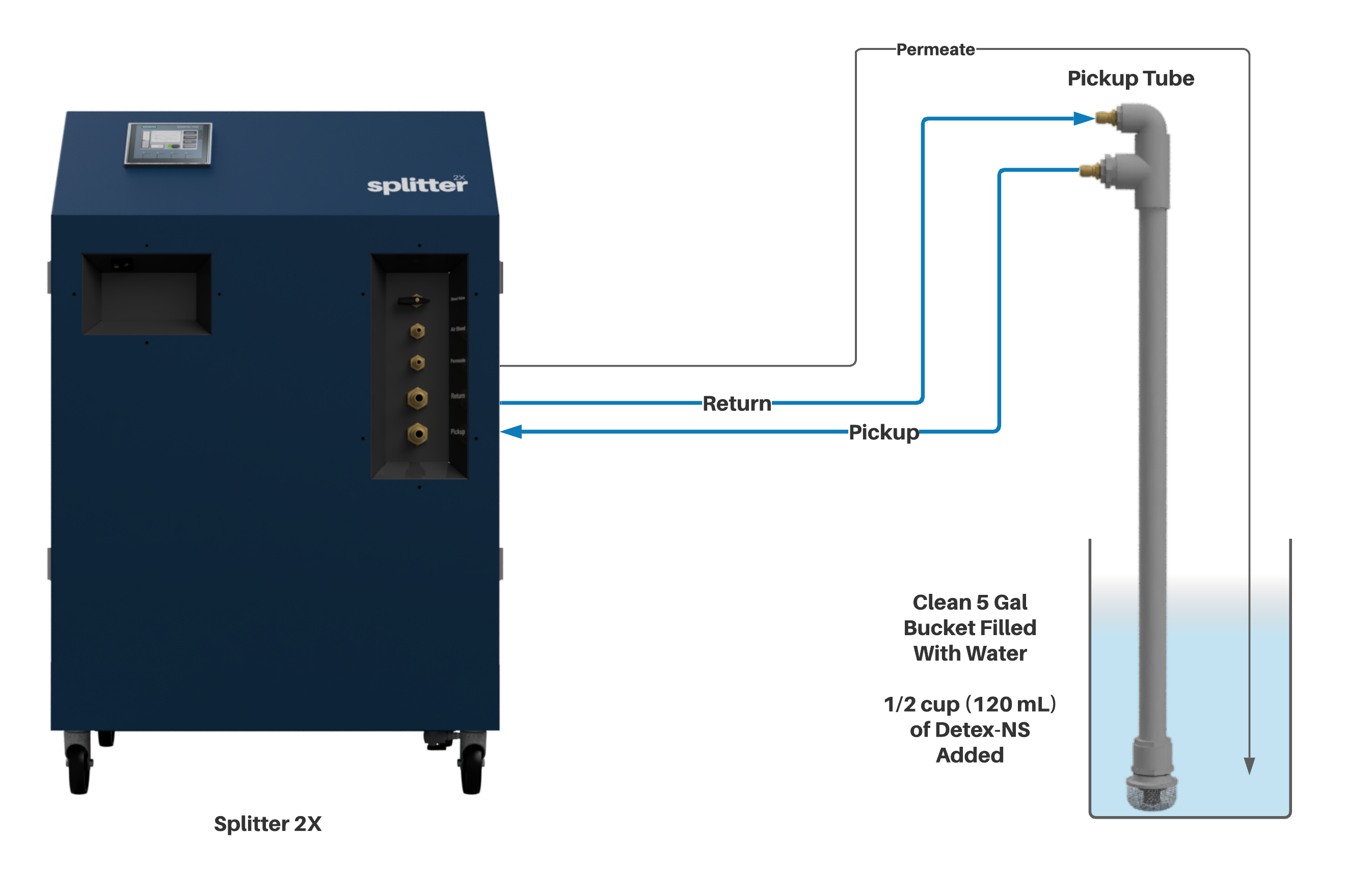

Detex-NS membrane cleaning solution is not added directly to the process tank. A cleaning cycle is recommended to be done once per week, by adding about a half cup of Detex-NS to a 5 gallon container filled with clean water. Once the cleaning cycle is done, this 5 gallons of waste can be added to the process tank to be treated with the next batch.

A 1 gallon container of Detex-NS should be good for about 8 months.

While the customer could definitely swap out the membranes each time, it is not something we would recommend. Changing out the membranes is a straight forward task, when done once or twice a year.

Frequent changeovers will wear out the seals and connection points. In the removal process, there is a slight chance of damaging the old membranes, which is normally a nonissue since they are to be discarded anyways but in this specific case, it would be highly undesirable.

The customer would also need to completely purge the system of any residual amounts of the previous waste, especially if transitioning from coolant waste to the penetrant waste. Membranes would also need to be stored submerged under clean water long term storage would require the addition of antibacterial and antifungal compounds to discourage organic growth.

In this scenario we would not be able to confidently claim a 6-12 month nominal lifetime for the membranes.

No, membranes are cleaned by "processing" a cleaning solution and should not be removed from the system. They should be cleaned once per week, or more frequently.

Yes, when the permeate rate no longer recovers to an acceptable rate after cleaning, the membranes should be replaced.

To purchase the Splitter™ Series Penetrant Waste Water Filtration System,

please contact us here: