The LP1 is the ideal stand-alone liquid penetrant inspection system for the low to medium volume user. Ideally suited for aircraft maintenance facilities, nondestructive testing labs, NDT schools and training institutes, government and military facilities, and more!

This system is designed with the needs of our client in mind. Extremely durable, user friendly and cost effective, making the LP1 the new go-to system in the industry.

Ideal For:

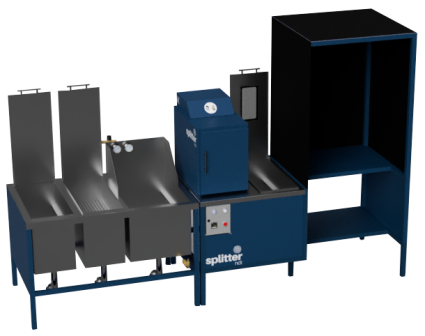

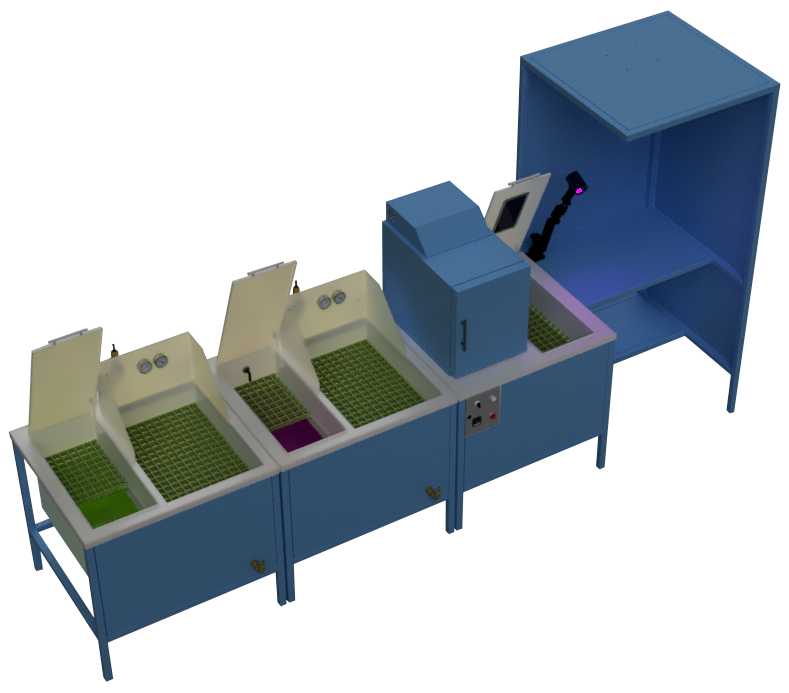

Pictured Above: Model LP1D

Pictured Above: Model LP1D

LP1A - 5 Stations, Method A

LP1B - 6 Stations, Method B

LP1D - 7 Stations, Method D

LP1D - 7 Stations, Method D

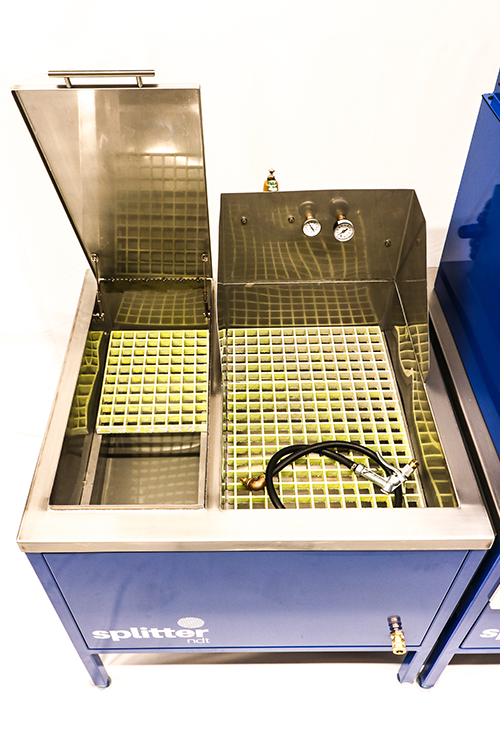

Dip Tank (with dwell) & Wash Station

Dip Tank (with dwell) & Wash Station

Dryer & Developer Stations

Dryer & Developer Stations

Full-Size Walk-In Inspection Booth

Full-Size Walk-In Inspection Booth

| Model | LP1A | LP1B | LP1D |

| Number of Stations | 5 | 6 | 7 |

| Stations Included |

|

|

|

| Number of Segments | 2 | 2 | 3 |

| Total System Dimensions | 110" x 36" x 85" | 135" x 36" x 85" | 150" x 36" x 85" |

| Dimensions of Each Station |

|

|

|

| Installation Requirements |

|

|

|