Sames - Excel Nanogun MV Manual Electrostatic Penetrant System

| | Benefits:

- Increased operator comfort

- Reduced fatigue

- Significant paint and air savings

- Suitable for high or low penetrant flow rates

- Great performance with high end production

- Easy to maintain:

- reduced number of components

- ready to spray after assembly

- perfect flushing

- smart diagnostics

|

|  |

|

Enhanced Ergonomics:

- Perfectly balanced

- Flexible Hoses

- Quick disconnect version

- Grip and barrel design

- Lightweight

|

New Control Module:

- Easy to maintain - Scheduled & Diagnostic alerts

- Easy to use

- kV setup value

- 3 presets

- Readable to 16.7 ft. (5 meters)

| Intuitive Control:

- High voltage On / Off

- Pattern Width

- Penetrant flow rate

- Super VORTEX technology

- Ready to spray after assembly

|

Apply Penetrant or Developer

| | Electrostatic application of dye penetrants and developers offers significant advantages over other methods of application for many users.

- Always applies fresh penetrant and developer

- Eliminates contamination

- Minimizes inventory - no tank to fill and maintain

- Minimizes penetrant usage by applying a thinner, more uniform penetrant film.

- 80-90% of the material goes on the part, minimizing waste and environmental contamination / pollution.

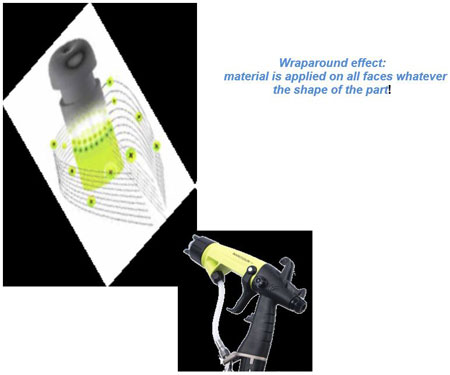

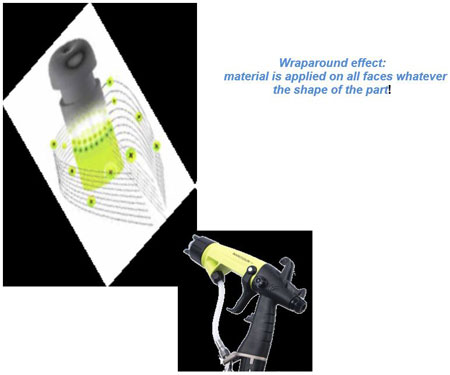

- Better coverage, penetrant wraps around the part which minimizes labor and time.

- Faraday Cage effect minimizes penetrant accumulation in holes.

|