- Home

- Magnetic Particle Equipment

- Wet Bench Machines

- DeltaFlux

- DeltaFlux MPI Systems

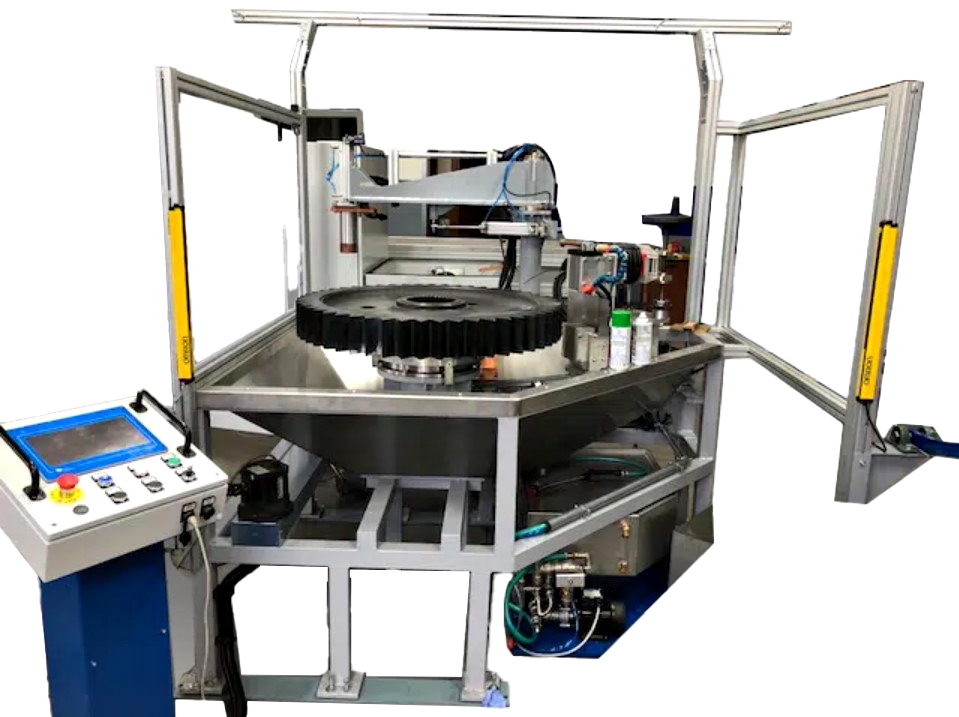

For Automated & Production Line applications, the MPI System is optimal. The MPI System a custom-built system. The purpose of the MPI System is to automate as many phases of Mag Particle Inspection as allowed by the parameters of the application. Phases of MPI that can be automated include:

The MPI System is equipped with a Control Panel touch screen for memory storage, current readings, and most importantly, programmable functionality for high repeatability and accuracy. Like the Magnetic Bench, the MPI System can be enclosed in a darkroom to allow for the operator to visually inspect pieces.

For Production Line and Automation Systems, the Magnetic Bench can be equipped with a Loading arm and Delta Touch Screen Control Panel for memory storage and operations for programming fully autonomous Non-Destructive Surface Inspection.

It is according to that particular piece – or to a specific continuous production cycle – that the system is engineered. For MPI of immovable/ fixed pieces, Portable Magnetic Generators can be used.

To inquire, please fill out the Discovery Form below with your required specifications, application, and functionalities: