| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| DeltaFlux Automated Inspection System | MT-DF-CIS |

|

Request Pricing | ||

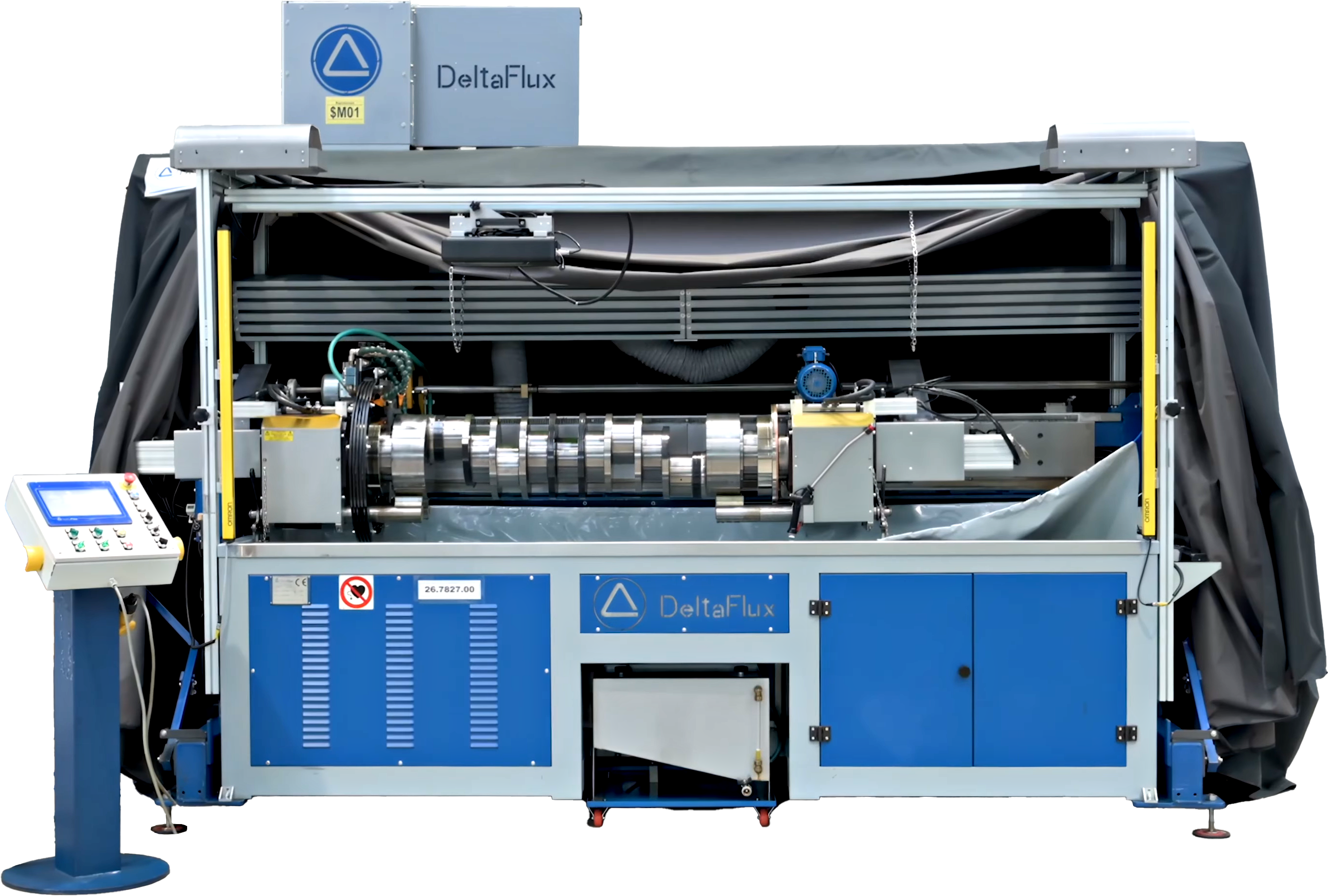

The DeltaFlux Automated Crankshaft Inspection System is a MPI bench designed for production inspection. The system combines automatic pole positioning, coil movement, particle application, part rotation and demagnetization into a one-touch operation, significantly reducing operator involvement and improving inspection consistency.

With automatic demagnetization at the end of each cycle, recipe storage, reporting capabilities, and remote connectivity, this Automated Inspection System is built for production environments requiring traceability and process control. Optional darkroom enclosures and UV lamp configurations are available.

The DeltaFlux Automated Inspection System Control Panel includes the following primary controls and functions, with custom inputs available:

| Main Controls | Touch Screen Functions |

|

|

| DeltaFlux Automated Crankshaft Inspection System Technical Specifications | |

| Product Range: | Crankshafts |

| Max Part Length: | 78.7" (2,000 mm) |

| Max Part Diameter Ø: | Ø13.8" (Ø350 mm) |

| System Dimensions (L x W x H): | 189" x 86.6" x 90.5" (4,800 x 2,200 x 2,300 mm) |

| Loading Capacity: | 772 lbs (350 kg) |

| Contact Pole Range: | 7.9" – 82.7" (200 – 2,100 mm) |

| Round Coil Diameter: | Ø17.7" (Ø450 mm) |

| Current Type: | AC (standard); DC Half-Wave or Full-Wave (optional) |

| Part Handling: | Manual loading using crane |

| System Interface: | Operator Panel |

| Electrical Supply: | 480V – 60 Hz – 3 phases + Earth |

| Pneumatic Supply: | 6 bar |

| Hydraulic Supply: | Not required |

To purchase or inquire about the DeltaFlux Crankshaft Inspection System, click below

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| DeltaFlux Automated Inspection System | MT-DF-CIS |

|

Request Pricing | ||