Hirsch Prueftechnik is a German based manufacturer specializing in the manufacture of Pulsed, Multi-direction, mobile magnetic particle testing machines. Dr. Peter Hirsch developed his first machine to enable safe testing of seam welds in submarines even in wet conditions. Multipuls machines use capacitor discharge to create a high power, short duration DC pulse of only a few milliseconds. Testing can be performed with fluorescent, visible, wet, or dry particles. Indications are sharp and clear. Even with their compact and mobile design, these units facilitate the testing of large surfaces.

Be it turbine construction, gear manufacturing, engine or mobile crane construction, galvanizing plants, offshore industry, aircraft industry, shipbuilding industry, or wind farm components; Hirsch's unique DC pulse technology facilitates economical and fast surface crack testing and subsequent demagnetization.

Magnetic Poles

Connect cables to the part.

Benefits include:

Technical Papers:

World Conference on Non-Destructive Testing Hirsch Technical Paper

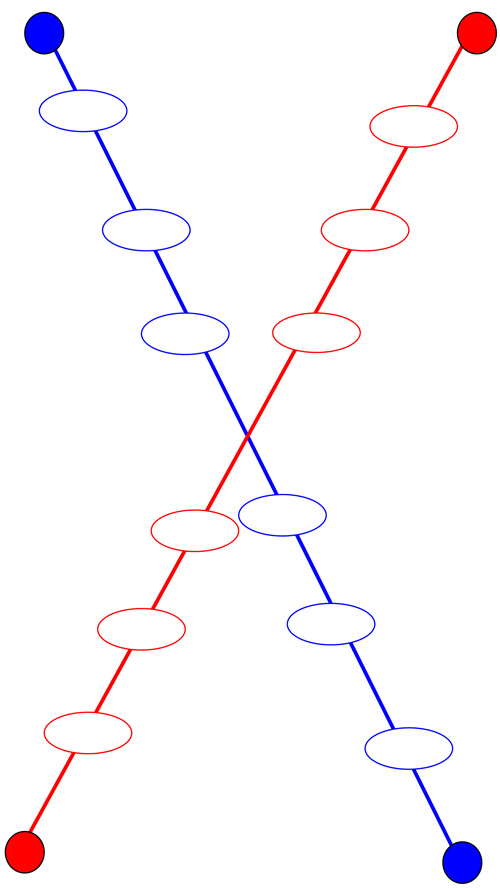

The 4 Pole Method is most suitable for planar components (left image) and is used for MT testing as well as demagnetization.

Perfect for magnetic particle testing and demagnetization. Benefits include:

Magnetizing Methods

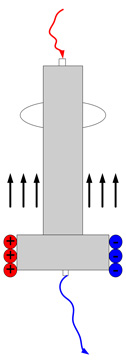

Direct Current Flow (4 Pole Method)

Combined Method

Contact Free Method

2-Box model with a DC power peak up to 8,000 A

Designed to fit through the hatch of a submarine and be safely used in wet tanks and structures

| Circuits | 2 - Multi-directional |

| Output | 500 - 8,000 Amp DC |

| Input | 220 VAC, 18 Amps |

| Duty Cycle | 50% |

| Field Strength | 12.5 – 100 Gauss |

| Frequency | 0.5-2 Hz |

| Pulses | 1-99 |

| Cables | 4 x 10 ft |

| Weight | 2 x 33 lbs |

| Size (WxHxD) | 10.4" x 12.8" x 14.4" |

(Left image) Testing of a rotor blade while assembled. This method of rotor blade testing saves time and installation effort.

DC power peak up to 20,000 A

With handles to be carried by 2 workers

| Circuits | 2 - Multi-directional |

| Output | 500 – 20,000 Amp DC |

| Input | 440/480 VAC, 32 Amps |

| Duty Cycle | 50% |

| Field Strength | 12.5 – 100 Gauss |

| Frequency | 0.5-2 Hz |

| Pulses | 1-99 |

| Cables | 4 x 10 ft. (or customer request) |

| Weight | 143 lbs. |

| Size (WxHxD) | 17.6” x 15.2” x 32” |

DC Pulse for MPI and Demag with up to 30,000 A

| Circuits | 2 - Multi-directional |

| Output | 500 – 30,000 Amp DC |

| Input | 440/480 VAC, 32 Amps |

| Duty Cycle | 70% |

| Field Strength | 25 – 100 Gauss |

| Frequency | 0.5-2 Hz |

| Pulses | 1-99 |

| Cables | 4 x 10 ft. opt. 16.7 ft. (or customer request) |

| Weight | 198 lbs. |

| Size (WxHxD) | 15.2” x 22” x 32” |

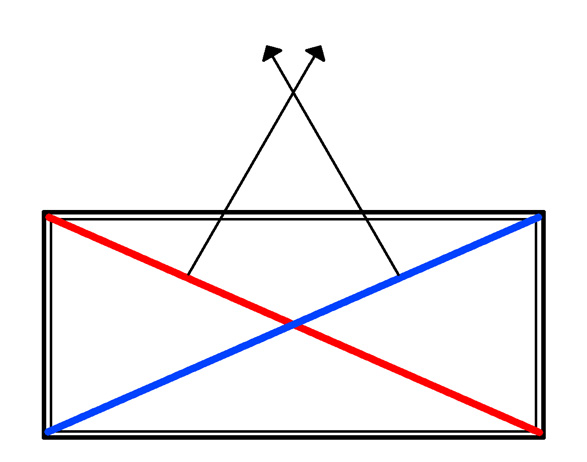

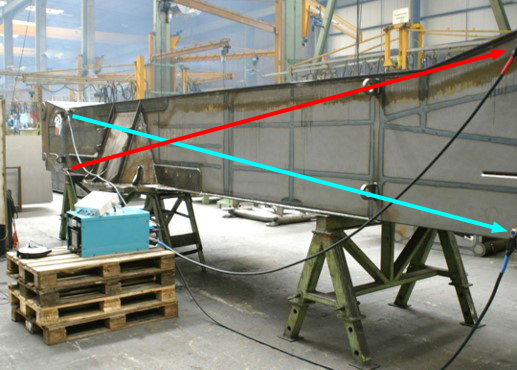

E2-1 testing welds of a 30 ft. long beam in one test. Connection points:

A circuit (Blue arrow), B circuit (Red arrow)

E2-1 testing of a over 13 ft. wide by 11 ft. high steel blade for a hydroelectric power plant. Connection points:

A circuit (Blue arrow), B circuit (Red Arrow)

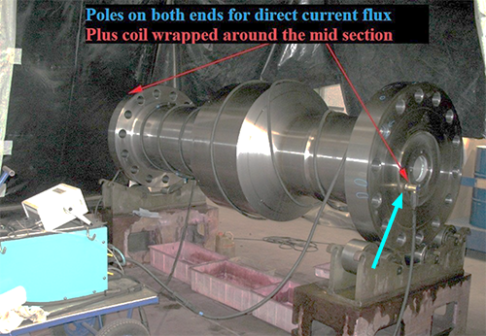

E2-1 testing a 3 ton shaft using a cable wrap and magnetic prods (blue arrow)

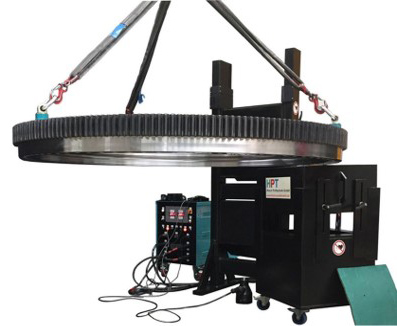

Contact free testing of large forging with Double Coils setup to create longitudinal and transverse magnetism

DC Pulse MPI on wheels, up to 30,000 Amps

| Circuits | 2 - Multi-directional |

| Output | 500 – 30,000 Amp DC |

| Input | 440/480 VAC, 32 Amps |

| Duty Cycle | 70% |

| Field Strength | 25 – 100 Gauss |

| Frequency | 0.5-2 Hz |

| Pulses | 1-99 |

| Cables | 4 x 10 ft. opt. 16.7 ft. (or customer request) |

| Weight | 325 lbs. |

| Size (WxHxD) | 20” x 36” x 36” |

Double Coil with longitudinal and transverse magnetization

AC & DC Pulse for MPI and Demag on wheels, with up to 30,000 A

| Circuits | 2 - Multi-directional |

| Output | 500 – 30,000 Amp AC/DC |

| Input | 440/480 VAC, 32 Amps |

| Duty Cycle | 70% |

| Field Strength | 25 – 100 Gauss |

| Frequency | 0.5-2 Hz |

| Pulses | 1-99 |

| Cables | 4 x 10 ft. opt. 16.7 ft. (or customer request) |

| Weight | 352 lbs. |

| Size (WxHxD) | 26.8” x 25.8” x 40” |

Demagnetization of a gas turbine rotor with a length of over 4 m using the Multipuls-1003-E2-3 device. The rotor had residual field strengths over 250 Gauss and was demagnetized below 4 Gauss

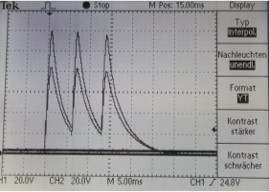

(Above) Current and field strength graph of the 3-DC-Pulse technology used by the Multipuls-1003-E3

Triple power DC Pulse with 3 X 30,000 Amp

The Multipuls-1003-E3 device was a development specifically for MPI work on large components with rough surfaces usually made in foundries. The Multipuls-1003-E3 utilizes a newly developed 3-DC-Pulse technology which greatly improves the quality of crack indications on large components with rough surfaces.

| Circuits | 2 - Multi-directional |

| Output | 3x 500 – 30,000 Amp DC |

| Input | 440/480 VAC, 32/63 Amps |

| Duty Cycle | 70% |

| Field Strength | 25 – 100 Gauss |

| Frequency | 0.5-2 Hz |

| Pulses | 1-99 |

| Cables | 4 x 10 ft. (or customer request) |

| Weight | 1100 lbs. |

| Size (WxHxD) | 26.8” x 25.8” x 40” |

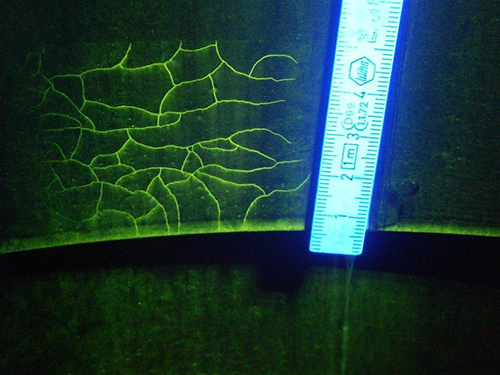

MPI performed with the Multipuls-E3 device on large components with rough surfaces in the foundry of Allard-Europe nv in Turnhout, Belgium

Pulse Test Currents, Pulse Test Field Strength and Residual Field Strength

HPT Hirsch Prüftechnik gauge makes relevant measurements for magnetic particle testing and demagnetization. This device is used for inertia-free and non-inductive measurement of pulse test current strength, pulse field strength, and residual field strength.

Measuring device for:

Testing of welded crane lattice mast constructions

MPI testing of elevator links measuring 12 m in length. During MT testing, they are being moved along underneath a box coil

To purchase Hirsch Multipuls machines, please contact us here: