| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| ETher Maxwell PECT In-Service Pulsed Eddy Current Inspection System | EC-ET-MAXWELL-PECT |

|

Request Pricing | ||

With unbeatable inspection capability and a truly simple user interface, the Maxwell PECT is an unmatched system in the field. A no nonsense, capable and flexible PEC inspection tool which has developed for harsh industrial environment inspections as well as applications in splash zones, subsea inspections and ROV deployments. The Maxwell PECT instrument is designed for the inspection of carbon steel and low-alloyed steels, which are magnetic. For magnetic test specimens, the eddy currents are concentrated on the surface directly after the magnetic pulse. Subsequently, the eddy currents diffuse into the test specimen, until the backwall is “found”. This results in a characteristic shape A-scan: a straight line, corresponding to the diffusion of the eddy currents, followed by curved section when the backwall is sensed. Weighing in at 7.5 kg (16.5lbs), including the batteries, the Maxwell system is highly portable; and with a typical battery life of 8 hours is an ideal inspection partner in the field.

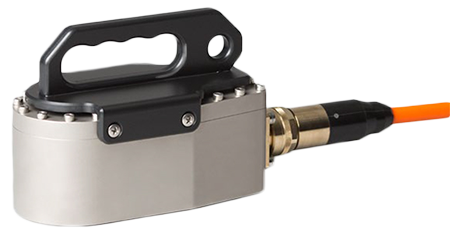

Underwater Probe set covering different depth ratings & lift-off ranges

Probes S, M, L and XL with and without encoder attachments

Pulsed Eddy Current Testing (PECT) is an inspection technique for inspecting carbon steel objects such as pipes and vessels, without the need for contact with the steel surface. PECT can measure percentage variations in steel thickness through any non-conductive and non magnetic materials between sensor and surface such as air, insulation material, concrete, plastics, coatings, sea water and marine growth, paint, deposits, oil, composite repairs, fireproofing, “scabs” aluminum sheeting and other non-magnetic insulation covers; so ideal for Corrosion Under Insulation (CUI) applications. Previous instruments often lacked the power to be fast and effective.

Using the latest battery technology, the Maxwell PECT is a novel and very powerful PECT instrument with a design based on 25 years’ hands-on experience at a global Oil Company.

Applications include:

In-Service PEC Inspection of Storage Tank Annular Rings

Maxwell NDT has developed a flat PEC probe that can be inserted underneath the annular ring of a tank floor for in-service inspection. The Maxwell PECT is powerful enough to measure through thick layers of corrosion products (iron oxides) underneath the tank floor, which is essential for annular ring inspection. The removal of corrosion materials is clearly unacceptable for in-service inspection, as this may trigger a leakage, but with the Maxwell PECT system this removal process is not required.

Advantages

| Hardware | |

| Data Acquisition Computer | DURABOOK U11i Touch screen with LED backlight Sunlight Readable Display. Ambient Light Sensor, screen protector, Navigation keypad/ “Quick” keys, 8GB memory, 250 GB SSD |

| Standard Probes | Four standard probes, types S (small), M (medium), L (large) and XL (extra large) Nominal lift-off ranges: (S)0-20mm (0 0.78ins); (M) 25mm-75mm (0.98-2.95ins); (L) 40mm-125mm (1.57-4.92 ins) and (XL) 75mm-250mm (2.95 9.84ins). Probe selection is automated in the set-up |

| Batteries | Main battery, typical life: 8 hours; external chargers ensure no down time due battery recharging. Hot-swappable. Computer battery is recharged automatically from the main battery, if charge drops below 20%, so no spare battery swap is required |

| Communication | Wi-Fi, Bluetooth, USB 3.0 |

| Environment | Meets IP65. Salt and Fog resistant |

| Operating Temperature | -4 to 104 °F (-20 to 40 °C) |

| Humidity and Pressure | Relative humidity < 93% Atmospheric pressure 70 – 105 kPa |

| Compliance | CE, RoHS, FCC Part 15B |

| Dimensions | 13" x 10.2" x 6" (33 cm x 26 cm x 15 cm) |

| Weight | 16.5 lbs. (7.5 kg) (includes batteries and data acquisition computer) The instrument is provided with 2 hoisting lugs |

| Transport of Standard Set | Operator transport is possible using the rucksack included in the set and instrument carrier belt. Air/Road transport in three Explorer cases (type 4830), 20" x 17.7" x 9.5" (52cm x 45 cm x 24cm). Weight 31 lbs. (14 kg) each |

| Transport of 25m Extension Lead | One Explorer cases 5823, 26.3" x 20" x 10.25" (67cm x 51 cm x 26cm) . Weight 15kg (33lbs). Cable is configured in a figure eight |

| Transport of Splash Zone Probes | One Explorer case, 7630, each 34" x 22" x 14" (86 cm x 56 cm x 36 cm) Weight 50m umbilical length: 68 lbs. (31 kg) |

| Operation and Software | |

| Measurement Parameters | Probe selection and measurement parameters are automatically set at start of an inspection using test measurements |

| Data Storage Software | All PECT signals are fully stored in data files for verification purposes |

| Data Collection Software | GUI user interface, Customizable Direct reporting to MS Excel |

| Data Collection Speed | Typical recording speed (second per reading): 0.19" <WT≤ 0.47" 0.5s (3mm< WT ≤12mm 0.5s) 0.47" <WT≤ 0.98" 1s (12mm< WT ≤25mm 1s) 0.98" <WT≤ 1.97" 2s (25mm< WT ≤50mm 2s) Note: the measurement time depends on a number of parameters that are hard to quantify, such as pipe vibration |

| Data Collection with Position Encoder | Data can be recorded with and without position encoder: Point-to-point measurements by manual or remote trigger. Dynamic Scanning: measurement triggered by encoder while moving the probe, ideal under favorable circumstances Stop & Go Data Collection: measurements triggered when encoder detects that probe is steady; applicable under less favorable circumstances |

| PC Reporting Software | Unlimited and license free copies of PC-based analysis software provided for Windows 10/ MS Excel |

| Report Generation | Microsoft Excel Reports are generated in both instrument software and PC-based analysis software. Report layouts can be customized |

| Language | English, French, Spanish and other languages available |

| Typical Performance Parameters | |

| Wall Thickness Range | 2-65mm (0-1.97in) steel |

| Maximum Lift-Off Range | 0-250mm for WT ≤ 15mm (0-9.84" for WT ≤ 0.6") 0-200mm for 15mm < WT ≤: 30mm (0-7.8" for 0.59" <WT ≤ 1.2") 0-100mm for 30mm < WT ≤: 65mm (0-3.9" for 1.18" <WT ≤ 1.97") |

| Minimum Pipe Diameter | 0mm (0") insulation: 25mm (1.0") 50mm (1.97") insulation: 75mm (3") 50mm (2.0") OD can be inspected with footprint around full pipe circumference |

| Insulation Sheeting | Aluminium & stainless. Performance on galvanized (magnetic) sheeting depends on properties |

| Footprint Diameter | Typically 1.5 times the thickness of the insulation, with a minimum of 25mm (0.98"). |

| Measurement Accuracy | PECT measures steel thickness averaged over it’s footprint area with a typical accuracy of ±10% |

| Robotic PECT General Info |

Compatible with probes, cables and software of portable PECT. Can be connected to maximum twelve (12) PECT probes; extension to maximum 48 probes is optional. Probes can record data in maximum four groups that are excited together. For example, the system can be configured to measure probes 1, 5 and 9 in cycle 1; subsequently probes 2, 6 and 10 in cycle 2; probes 3, 7 and 11 in cycle 3 and probes 4, 8 and 12 in cycle 4. Other grouping is possible. One on-board industrial computer for the data acquisition program. Connection to master computer with Ethernet communication. Two encoder inputs. Three digital out signals (TTL), which can e.g. be used for motor control. Is supplied with electronics board mounted on a frame, selected internal connectors are accessible to the user for (re)-configuration by the user. Full documentation of the electronics connections is provided with the set. Housing can be re-arranged to suit operator needs. |

| Optional Items | Same as portable topside MAXWELL PECT Underwater housing for different depth ratings |

| Data Acquisition Computer | POC 212. 8 GB memory, 250 GB SSD control via LAN network Option to connect to another data acquisition computer (requires Window 10); software key which is required will be provided for free |

| Probes | Compatible with all MAXWELL NDE probes |

| Communication | Ethernet & RS485 (not standard) |

| Environment | The Robotic system is delivered on a frame, which is designed for placing in a pressure housing. Housing can be in pressure containers, depending on the customer requirements such as number of probes, application above or below water and depth rating |

| Temperature | -4 to 122 °F (-20 to 50 °C) |

| Humidity and Pressure | Relative humidity < 93% Atmospheric pressure 70 – 105 kPa |

| Compliance | CE, FCC Part 15B |

| Dimensions | 20" x 6" ᴓ6" (510mm x 150mm ᴓ150mm) |

| Weight | 28 lbs. (12.7 kg), including batteries and data acquisition computer |

Transport Case 1: PECT instrument, optional tank floor probe, computer mouse, battery charger and AC adapter

Transport Case 2: Two NiMH batteries, four standard probes, connector piece and documents. Probe and encoder compartment

Transport Case 3: Contains two 8m long Signal cables, reference plate, encoder plates and a rucksack

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| ETher Maxwell PECT In-Service Pulsed Eddy Current Inspection System | EC-ET-MAXWELL-PECT |

|

Request Pricing | ||