| TCM Test Channel |

| Frequency Range: |

4 Hz – 20 MHz adjustable in 1 Hz steps |

| Multi-Frequency: |

- Up to 8 frequencies in parallel

- Mix two frequencies for reducing disturbing signals

|

| Filter: |

Low-pass filter and high-pass filter 1 Hz – 20,000 Hz |

| Gain: |

-20 dB to +120 dB in 0.1 dB steps |

| Phase: |

0° – 360° in 0,1° steps |

| X and Y Gain: |

0 – 60 dB in 0,1 dB steps |

| X/Y Offset: |

-50/50 in 5 % steps |

| Probe Recognition: |

Automatically adjusts pre-amplifier, max output current |

| Pre-Amplifier: |

-18, -12, -6, 0, 6, 12, 18, 24, 30, 36 dB |

| Max Output Current: |

400 mA (peak), 10 V peak-peak |

| Data Resolution: |

32 bit |

| Sample Rate: |

Up to 40,000 samples/ second |

| Trace Time: |

0.1 – 60 seconds, Infinite, Rot-Sync |

| Charts: |

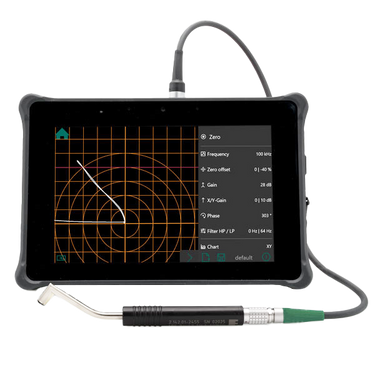

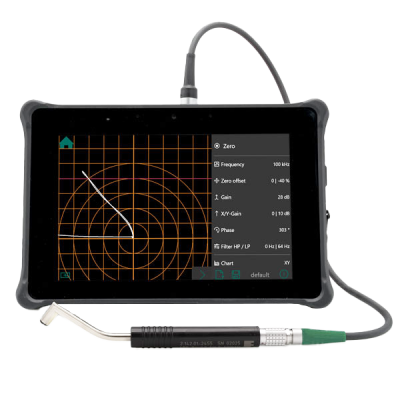

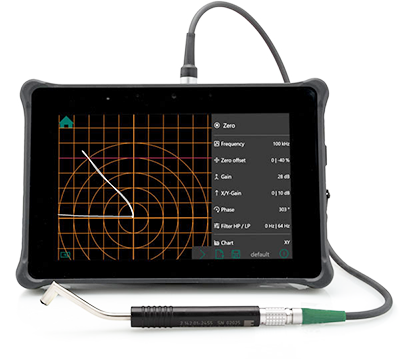

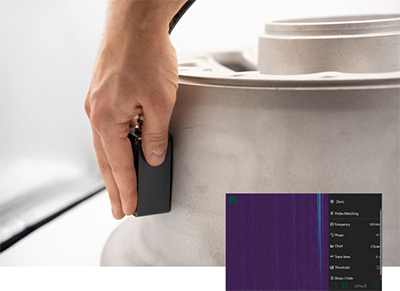

x/y, t, x/y + t, C-scan |

| Thresholds: |

Lines, circle, box, sector |

| Freeze Mode: |

Freeze your signal and adjust parameters like gain and phase |

| Documentation: |

- Customizable PDF reporting

- Take screenshots as PNG

- Record raw data and load them afterwards for further analysis

- Automatic documentation of all eddy current parameters

|

| Array Technology: |

Up to 512 probe elements |

| Supported Probes: |

- Rotating head and probes (5 – 24 V)

- All separate transmit-receive probes (reflection) e.g. absolute, differential and parametric probes like DEFECTOMETER probes

- Bridge probes (adjustable resistance 5, 25, 50, 100, 200 Ω)

- Probes from other manufacturers are compatible with TCM

|

| Conductivity Measurement Frequency: |

60, 120, 240, 480 kHz |

| Conductivity Measurement Accuracy: |

+/- 1.0s% of measured value at 60 kHz, 14 mm probe |

| Conductivity Measurement Resolution: |

+/- 0.1% of measured value |

| Conductivity Measurement Range: |

0.5 to 65 MS/m (1-112% IACS) |

| Wizards: |

Auto-set wizard for:

- absolute probe and lift-off setup

- setting up filters for rotating probes

|

| Fulfilled Standards: |

DIN EN ISO 15548

|