| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| Rohmann EloWheel RPT17 Wheel Rim Inspection System | EC-RM-RPT17 |

|

Request Pricing | ||

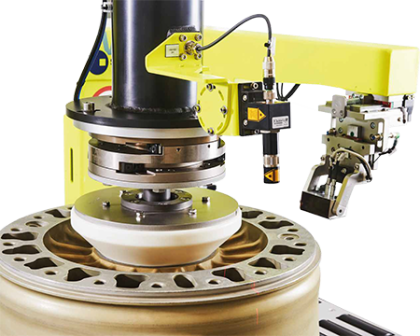

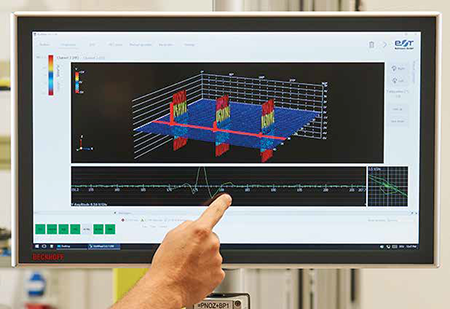

Rohmann's new RPT17 Aircraft Wheel Inspection System is developed and manufactured in Germany. The system is the successor of the RPT16 - which is fabricated in the US and still placed on the market - and provides numerous innovations. Using a modern eddy current testing instrument, the surface as well as the volume of the wheel rims is inspected by both, a high frequency and a low frequency probe simultaneously. The rapidity of the inspection, the sensitivity of the defect search, the resolution and the reliability as well as the flexibility in the adaptation to different requirements are the key benefits of the inspection system. By using a dual probe, the new ELOWHEEL 800 RPT17 makes it possible to inspect aircraft wheel rims (up to a diameter of 800 mm) for the detection of cracks on the surface and also defects inside the material at the same time. The user-friendly interface is integrated into the tried and tested ELOWHEEL evaluation software and its arrangement is perfect for inspecting wheel rim halves quickly and safely for different types of defects.

Inspection for the detection of surface cracks (HF inspection)

Inspection for the detection of hidden defects (LF inspection)

The entire system is operated via a 24 inch touch screen with our EloWheel software. The software provides known functions such as:

| Operation Temperature | 10-40 C |

| Operation Humidity | 80% |

| Electrical Connection | 400V AC, 16 A (Separate N and GND) |

| Compressed Air | 6 bar minimum, clean and dry |

| Space Requirements (LxWxH) | 1780 x 1425 x 2980 mm |

| Rim Halves | Diameter: 800 mm max Height: 500 mm max Weight: 250 kg max |

| Parameter Sets | 3 min max |

| Inspection Cycles of Rim Halves | 2 min max |

| RPM | 120 max |

| Description | Part # | Saved | Price | Select Option | Add to |

|---|---|---|---|---|---|

| Rohmann EloWheel RPT17 Wheel Rim Inspection System | EC-RM-RPT17 |

|

Request Pricing | ||