The Advanced Wheel Tester AWT 950 NG is designed for automated Eddy Current Testing of aircraft wheels with a maximum diameter of 950mm (37.40"). Testing capacities include Nose Landing Gear and Main Landing Gear for all main wheel manufacturers including Goodrich, Honeywell, and Messier-Bugatti-Dowty.

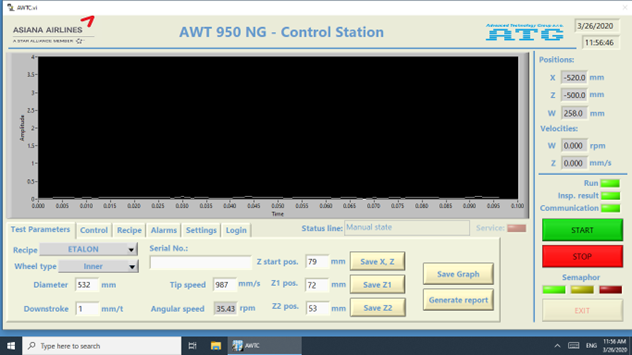

The Touchscreen Controls include a suite of standard inspection controls as well as the ability to create and save functions for easy repeatability. The software runs on the Windows operating system.

Inspection reports are automatically recorded and saved.

| AWT 950 NG Technical Specifications | |

| Diameter range of tested wheels: | 5.9 - 37.4 inches (150 mm - 950 mm) |

| Loading limit: | 264.56 lbs (120 kg) |

| Maximum rotation speed: | 90 rpm |

| Operating air pressure: | 3.5 up to 6 bar |

| Consumption: | 5 kVA |

| Min. detection depth ability for following horizontal: | 0.03 +/- 0.002 inches (0.76 +/- 0.05 mm) |

| Defect width size by KDB probe on the reference: | 0.004 +/- 0.002 inches (0.1 +/- 0.05 mm) |

| Wheel length: | 1.52 +/- 0.05 mm |

| Axis Z ensures vertical movement of probe: | scanning of disc surface during rotation – motorized in range 450 mm |

| In Spiral: | vertically |

| Rotary testing speed is adjustable: | between 10 up to 90 rpm for the smallest diameter of a wheel |

The AWT 950 NG enables automatic testing of front and main aircraft wheels from all primary manufactures of wheels for Boeing, Airbus etc. e.g. Goodrich, Honeywell, Messier and others. They are:

| Aircraft: | B787 | A380 | A330 | B748 | B777ER | B744 | B737 |

| Wheel Weight: | 55kg | 87kg | 58kg | 76kg | 68kg | 59kg | 39kg |

| Wheel Height: | 423mm | 390mm | 355mm | 400mm | 370mm | 340mm | 290mm |

| Diameter: | 700mm | 710mm | 690mm | 675mm | 680mm | 660mm | 610mm |

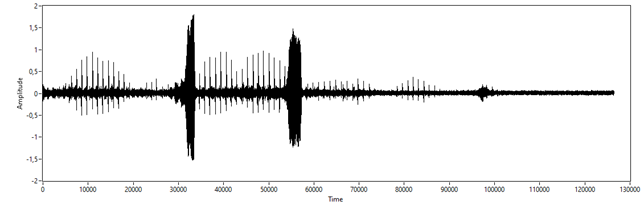

Reference standard on a Wheel: Automatic Reference Standard above is attached a wheel for enhanced referencing

3 EDM horizontal defects in 3 different location

Depth: 0.76 +/- 0.05 mm

Width: 0.10 +/- 0.05 mm

Length: 1.52 +/- 0.05

For more information, please contact us