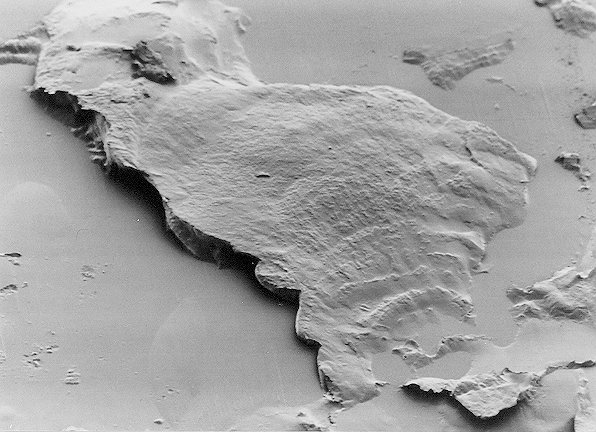

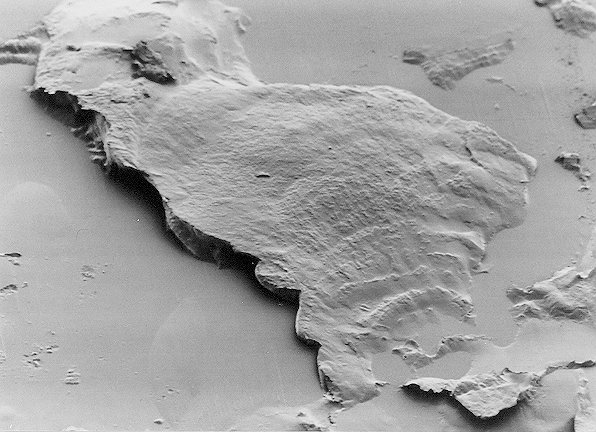

Fatigue pitting on a gear tooth surface SEM x100

Replica Examination

When viewed microscopically under coaxial illumination, Microset replicas have a bright metallic appearance, allowing detail such as microstructure, micro-cracking and pitting to be observed at high magnifications. These characteristics make Microset replication ideal for the assessment of defects on critical engineering surfaces. Microset replicas can be examined using various techniques including: Microscopy, Stereo Macroscopy, 3D Infinite Focus Microscopy, Scanning Electron Microscopy, Atomic Force Microscopy, White Light Interferometry, Shadowgraph Measurement and 3D Laser Measurement.