The Affri 206 RSD, 330 RSD and 903 RSD Semi-Automatic Rockwell Hardness Testers are usable for Rockwell, Brinell and Vickers hardness testing methods in compliance with ASTM and ISO standards. These bench-style hardness testers are ideal for lab applications or tough environments. Accuracy is better than 0.5% in all conditions - the first time, every time - eliminating the need for repeated tests.

How it Works:

Load forces are applied through a dynamometric load cell which eliminates problems associated with dead weight systems on traditional testers. Features a digital durometer with LCD screen, user friendly interface, real time statistics, graphs and large archive storage. Effectively tests all metals: iron, steel, tempered steel, cast iron, brass, aluminum, copper and metal alloys. Also features heat treatment, hardening, nitriding, cementation and hardfacing.

206 RSD

Hardness Tester with elevating screw and 8.5" (215 mm) height capacity

330 RSD

Hardness Tester with a large base and head vertical stroke of 15" (380 mm)

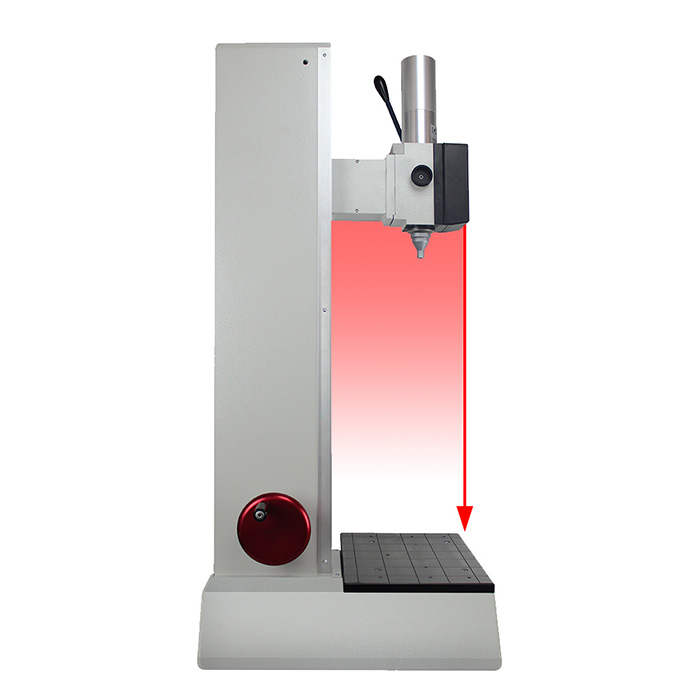

903 RSD

Hardness Tester with a large base and head vertical stroke of 27.6" (700 mm)

Load forces: from 3 to 187.5 kgf (From 29.42 to 1,839 N)

Rockwell ISO 6508 / ASTM E-18: HRA - HRB - HRC - HRD - HRF - HRG - HRL - HRM - HRR / HRN - HRT

Brinell HBWT ISO 6506 / ASTM E-10: HB 30 - HB 10 - HB 5 MPa (F/D2)

Vickers ISO 6507 / ASTM E-384 (Only indentation): HV3 - HV10 - HV15 - HV30 - HV60 - HV100

Software: The software controls the whole instrument during the entire cycle avoiding operator errors. Through the user interface, you can set the hardness test method, measurement settings, access and save storable and printable statistics and view results, averages and conversions

Manual Drive and Automatic Cycle

Just pull the START lever and the hardness tester's head moves down to make contact with the sample's surface, locking it. The hardness test cycle will automatically begin without breaching a phase. Within seconds results appear.

On the 206 model, instead you will push the appropriate buttons on the interface, then elevate the screw so that the component is in contact with the indenter. Once you've done that, pull the lever back - results will appear just as quickly.

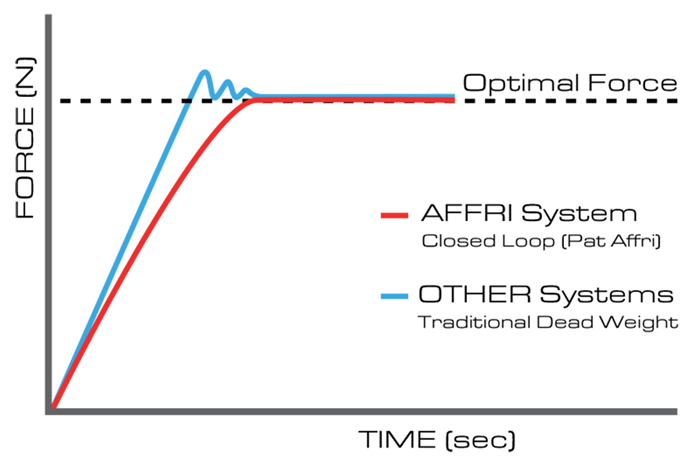

The Affri System

Load forces are generated by a dynamometric load cell which assures long term accuracy and eliminates problems associated with dead weight systems on traditional testers. Results are not affected by any structural deflection, misalignment or vibration.

Repeatability & Reproducibility

Accurate measurements on the first test, even in extreme conditions, will eliminate the need for repeated tests. The R&R data is at the top of its class.

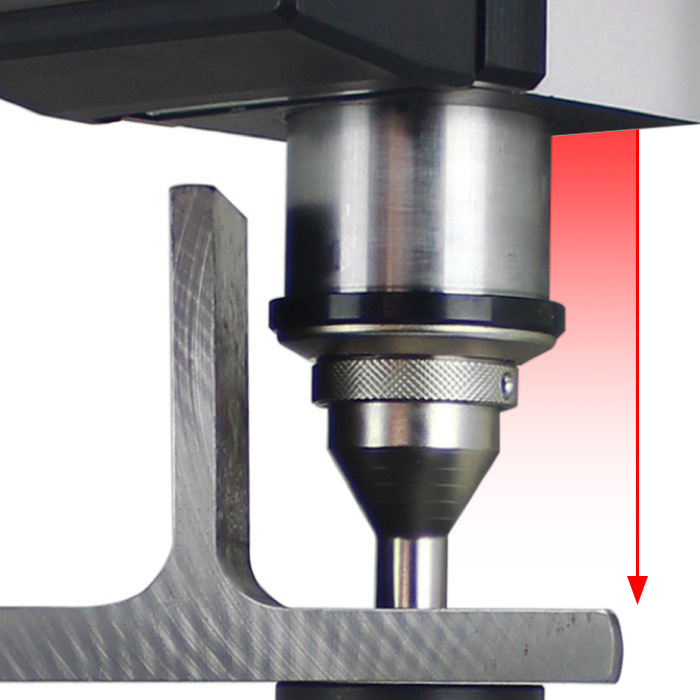

Indenter Stroke

When testing unstable samples or deflecting parts, the AFFRI System will follow the sample without losing contact thanks to its 2" (50 mm) stroke for indenter and clamping hood. Easy and fast hardness measurements on pieces with different thicknesses without acting on tester head or elevating screw.

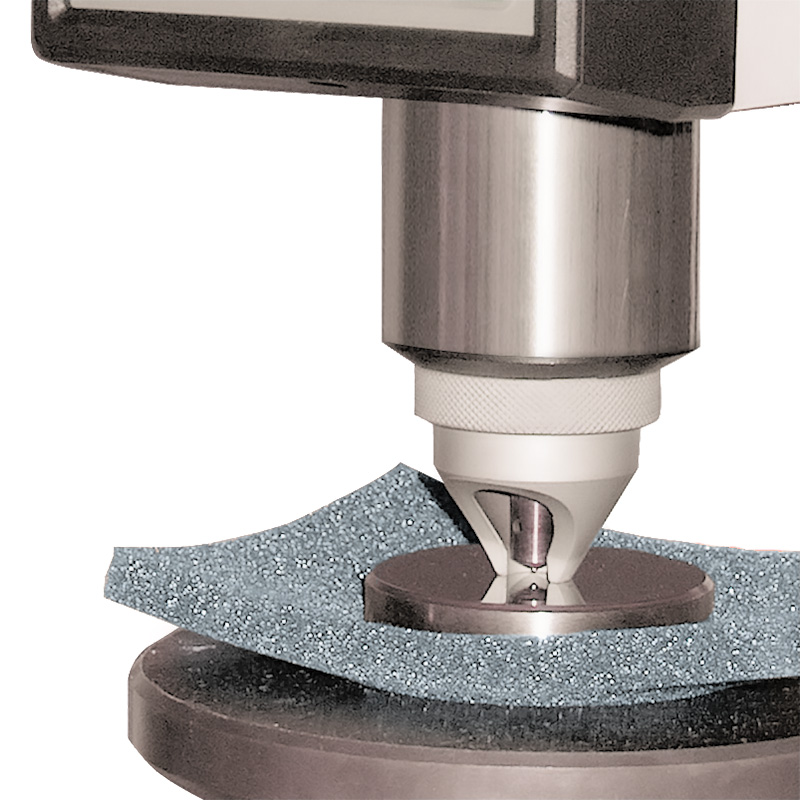

Clamping System (Pat. Affri)

Secure contact with the specimen is always maintained, even in the unlikely event of any specimen movement during the operation cycle. The clamping system assures perfect stability of any test piece throughout the test cycle, even if it's oiled, rusty or dirty.

Moving Tester's Head

On the 330 and 903 models, the tester's head can be adjusted. The 330 has a maximum head adjustment of 15" (380 mm), and the 903 has a maximum head adjustment of 27.5" (700 mm). The adjustable tester's head permits easy measurements on large pieces, reaching points at the top of the sample that would be difficult to be measured with common testers.

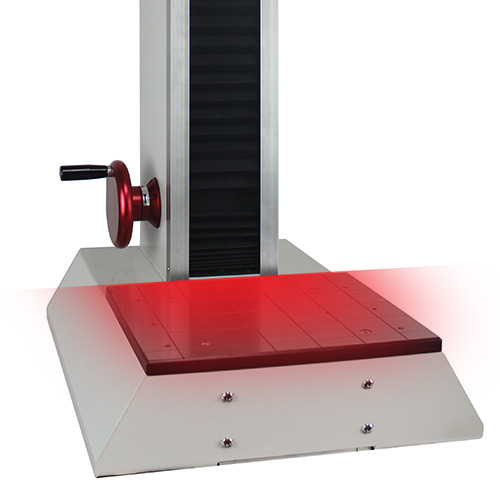

Large Base

The 330 and 903 RSD’s wide work table base is capable of bearing masses beyond 2,204 lbs (1,000 kg) which allows for steady hardness measurements on bulky or irregular pieces It also offers a comfortable working base for small pieces.

Optional Table for Ring Shaped Samples

Optional interchangeable base for hardness testing on external ring shaped tubes, cylindrical surfaces and various sample diameters.

| Affri 206 RSD / RS-SD Specifications | |

| Standards | EN-ISO 6506-2 / EN-ISO 6507-2 / EN-ISO 6508-2 / ASTM E-18 / ASTM E-10 / ASTM E384/ JIS |

| Indenter and Clamping-Hood Stroke | 13" - 15.5" (330 x 390 mm) |

| Elevating Screw Stroke | 0" - 8.5" (0 / 215 mm) |

| Depth Capacity | 7.5" (190 mm) |

| Preload (RSD) | 98.1 N (10 kgf) |

| Preload (RS-SD) | 29.4 (3 kgf) |

| Force Range (RSD) | Rockwell: 588.4 - 980.7 - 1471 N (60 - 100 - 150 kgf) Vickers (Only indentation): 98.07 - 980.7 N (10 - 100 kgf) Brinell (On request): 98.07 - 612.9 - 1226 - 1839 N - On request 2452 N (10 - 62.5 - 125 - 187.5 kgf - On request 250 kgf) |

| Force Range (RS-SD) | Superficial Rockwell: 147.1 - 294.2 - 441.3 N (15 - 30 - 45 kgf) Vickers (Only indentation): 29.42 - 294.2 N (3 - 30) Brinell (On request): 153.2 - 294.2 - 306.5 N (15.6 - 30 - 31.2 kgf) |

| Feasible Tests (RSD) | Rockwell: HRC - HRA - HRD - HRB - HRF - HRG - HRL - HRM - HRR Vickers (Only indentation): HV10 - HV100 Brinell (On request): HB30 - HB10 - HB5 MPa (F/D2) |

| Feasible Tests (RS-SD) | Superficial Rockwell: HRN - HRT Vickers (Only indentation): HV3 - HV30 Brinell (On request): HB30 - HB10 - HB5 MPa (F/D2) |

| Load Accuracy | Better than 0.5% |

| Affri 330 RSD / RS-SD Specifications | |

| Standards | EN-ISO 6506-2 / EN-ISO 6507-2 / EN-ISO 6508-2 / ASTM E-18 / ASTM E-10 / ASTM E384/ JIS |

| X-Y Table | 13" - 15.5" (330 x 390 mm) |

| Indenter and Clamping-Hood Stroke | 0" / 2" (0 / 50 mm) |

| Vertical Head Stroke | 0" - 11.8" (0 / 300 mm) |

| Depth Capacity | 7.5" (190 mm) |

| Preload (RSD) | 98.1 N (10 kgf) |

| Preload (RS-SD) | 29.4 (3 kgf) |

| Force Range (RSD) | Rockwell: 588.4 - 980.7 - 1471 N (60 - 100 - 150 kgf) Vickers (Only indentation): 98.07 - 980.7 N (10 - 100 kgf) Brinell (On request): 98.07 - 612.9 - 1226 - 1839 N - On request 2452 N (10 - 62.5 - 125 - 187.5 kgf - On request 250 kgf) |

| Force Range (RS-SD) | Superficial Rockwell: 147.1 - 294.2 - 441.3 N (15 - 30 - 45 kgf) Vickers (Only indentation): 29.42 - 294.2 N (3 - 30) Brinell (On request): 153.2 - 294.2 - 306.5 N (15.6 - 30 - 31.2 kgf) |

| Feasible Tests (RSD) | Rockwell: HRC - HRA - HRD - HRB - HRF - HRG - HRL - HRM - HRR Vickers (Only indentation): HV10 - HV100 Brinell (On request): HB30 - HB10 - HB5 MPa (F/D2) |

| Feasible Tests (RS-SD) | Superficial Rockwell: HRN - HRT Vickers (Only indentation): HV3 - HV30 Brinell (On request): HB30 - HB10 - HB5 MPa (F/D2) |

| Load Accuracy | Better than 0.5% |

| Affri 903 RSD / RS-SD Specifications | |

| Standards | EN-ISO 6506-2 / EN-ISO 6507-2 / EN-ISO 6508-2 / ASTM E-18 / ASTM E-10 / ASTM E384/ JIS |

| X-Y Table | 13" - 15.5" (330 x 390 mm) |

| Indenter and Clamping-Hood Stroke | 0" / 2" (0 / 50 mm) |

| Vertical Head Stroke | 0" - 27.5" (0 / 700 mm) |

| Depth Capacity | 7.5" (190 mm) |

| Preload (RSD) | 98.1 N (10 kgf) |

| Preload (RS-SD) | 29.4 (3 kgf) |

| Force Range (RSD) | Rockwell: 588.4 - 980.7 - 1471 N (60 - 100 - 150 kgf) Vickers (Only indentation): 98.07 - 980.7 N (10 - 100 kgf) Brinell (On request): 98.07 - 612.9 - 1226 - 1839 N - On request 2452 N (10 - 62.5 - 125 - 187.5 kgf - On request 250 kgf) |

| Force Range (RS-SD) | Superficial Rockwell: 147.1 - 294.2 - 441.3 N (15 - 30 - 45 kgf) Vickers (Only indentation): 29.42 - 294.2 N (3 - 30) Brinell (On request): 153.2 - 294.2 - 306.5 N (15.6 - 30 - 31.2 kgf) |

| Feasible Tests (RSD) | Rockwell: HRC - HRA - HRD - HRB - HRF - HRG - HRL - HRM - HRR Vickers (Only indentation): HV10 - HV100 Brinell (On request): HB30 - HB10 - HB5 MPa (F/D2) |

| Feasible Tests (RS-SD) | Superficial Rockwell: HRN - HRT Vickers (Only indentation): HV3 - HV30 Brinell (On request): HB30 - HB10 - HB5 MPa (F/D2) |

| Load Accuracy | Better than 0.5% |

For more information on purchasing the Affri 206 RSD, 330 RSD or 903 RSD Semi-Automatic Rockwell Hardness Testers, please contact us here: